COC USA

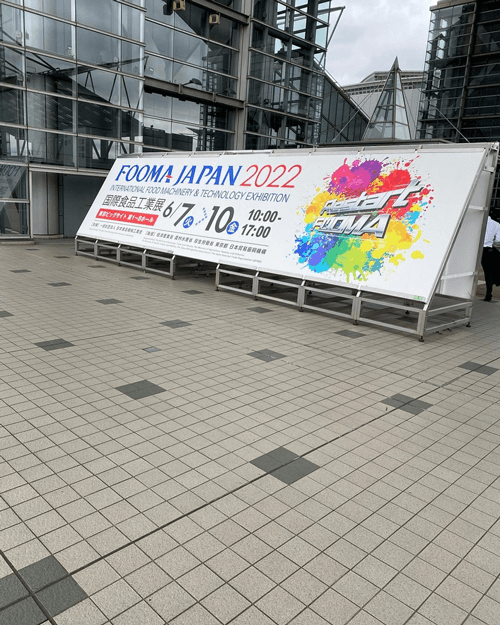

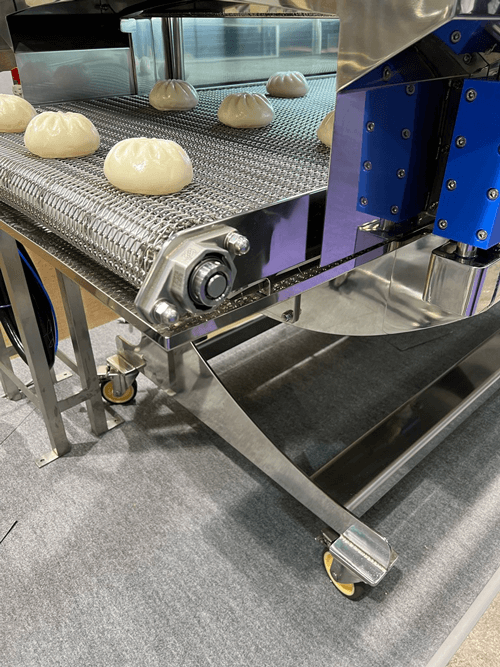

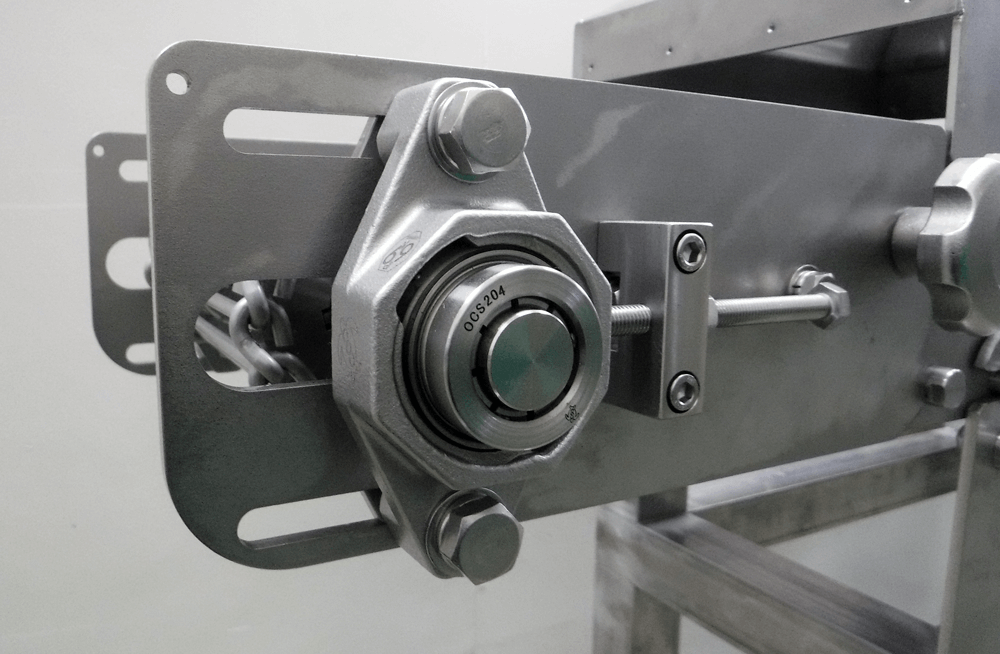

COC USA opens October 2022

COC bearings finally crosses the Pacific Ocean to the United States.

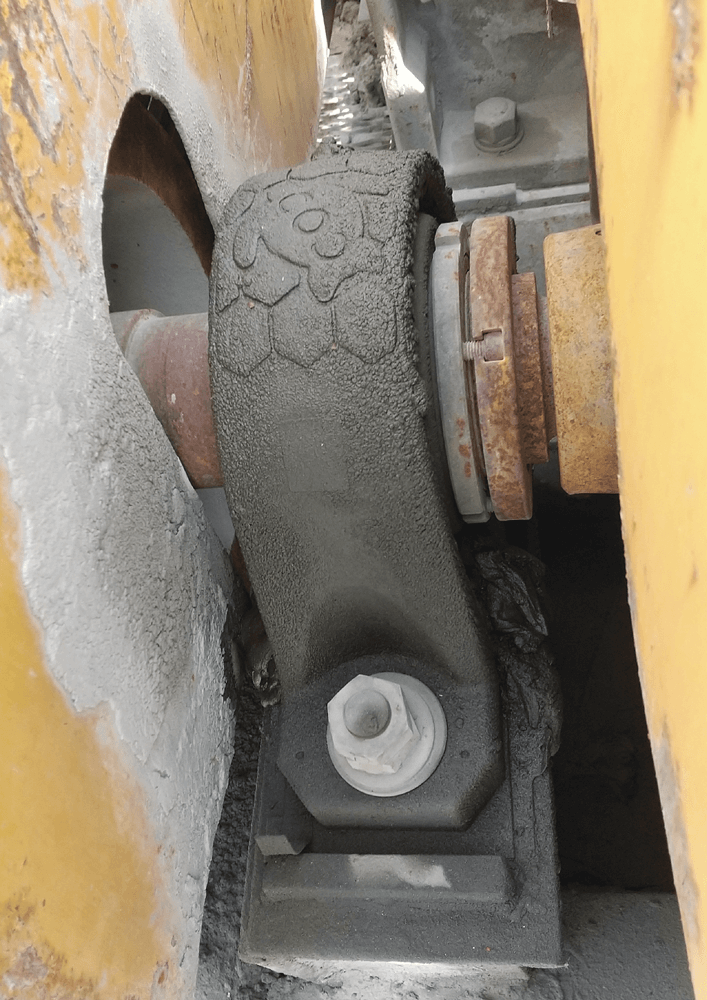

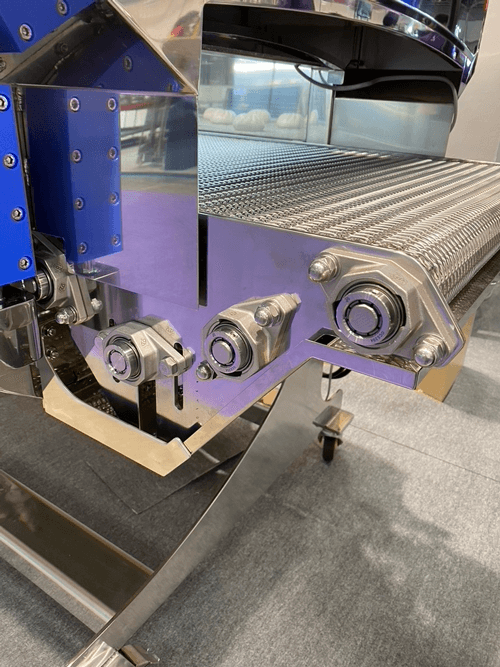

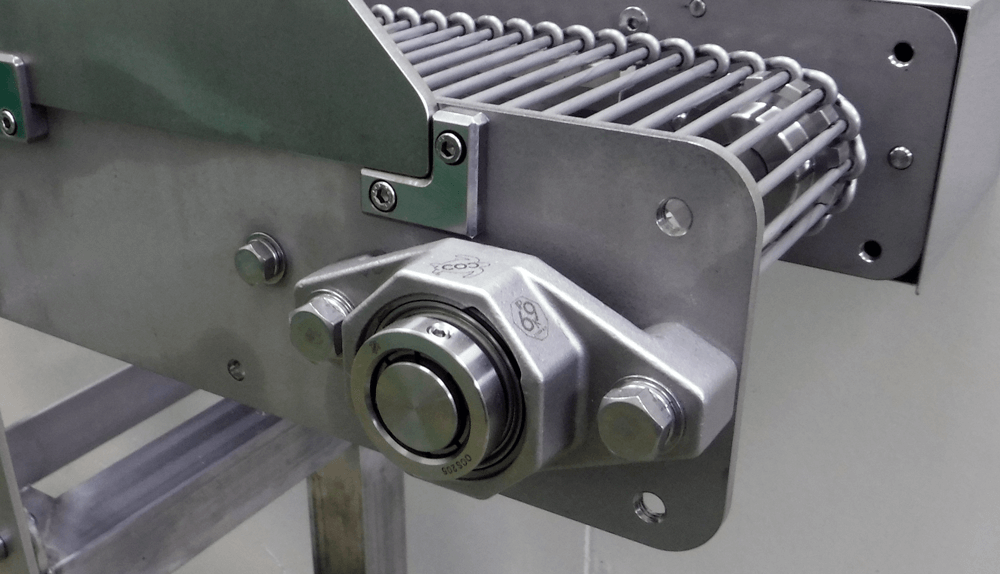

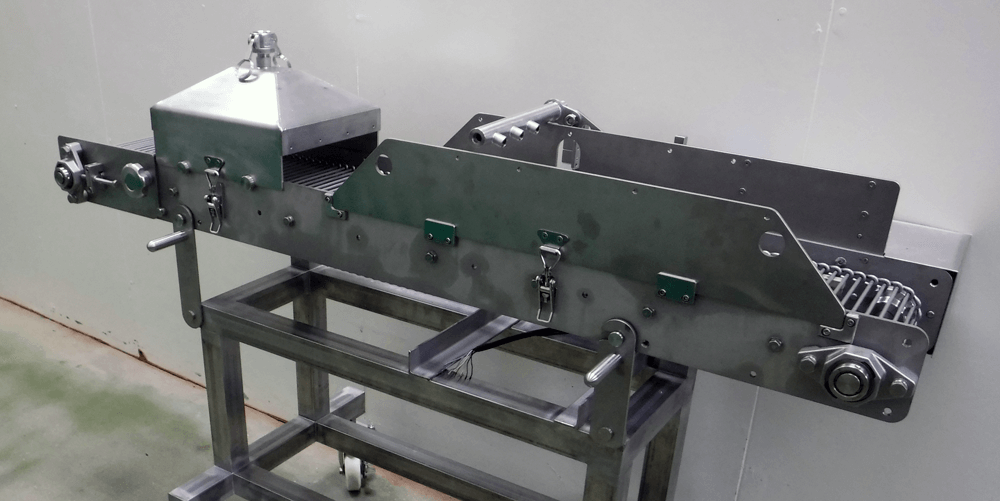

Serving the next generation of bearing products throughout the country.

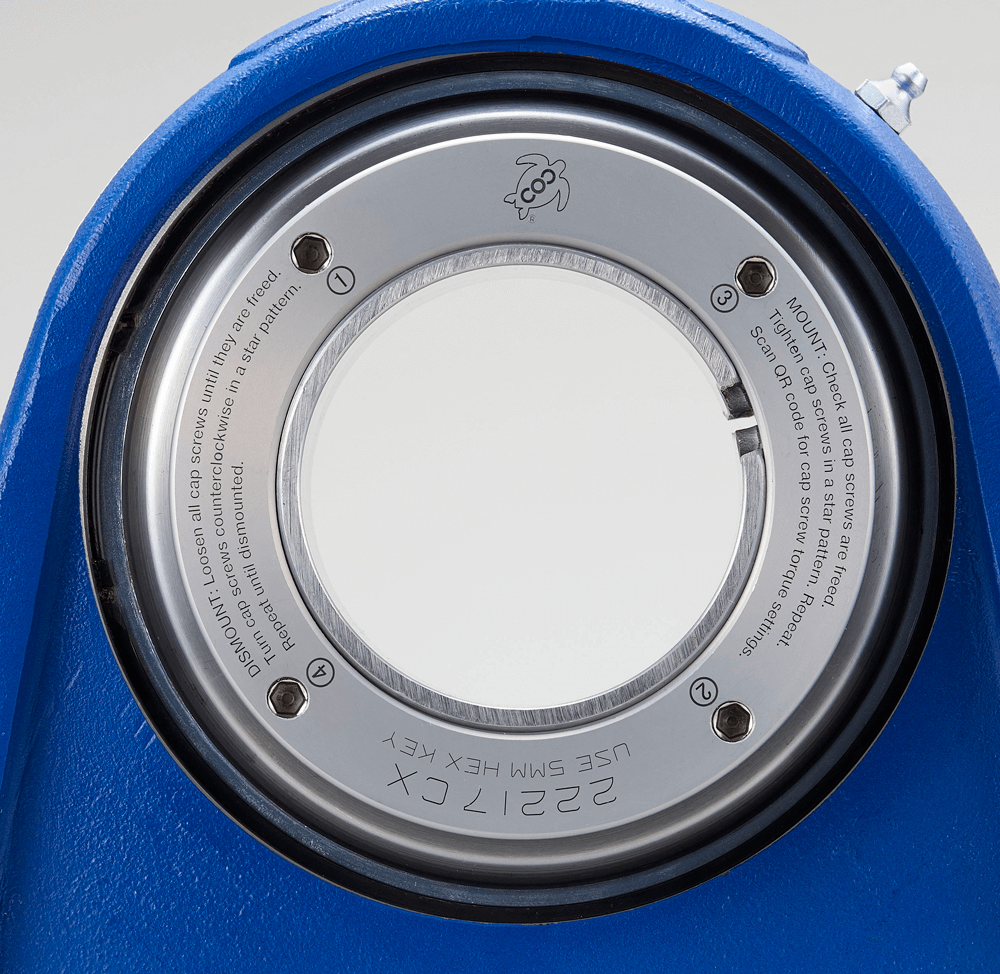

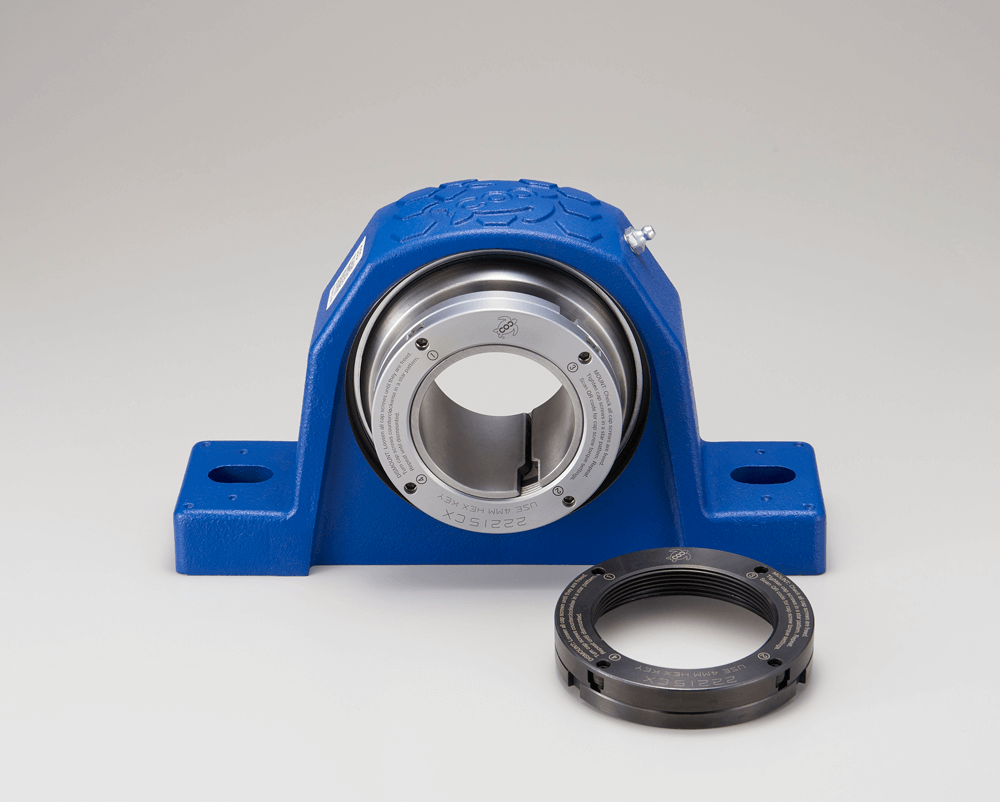

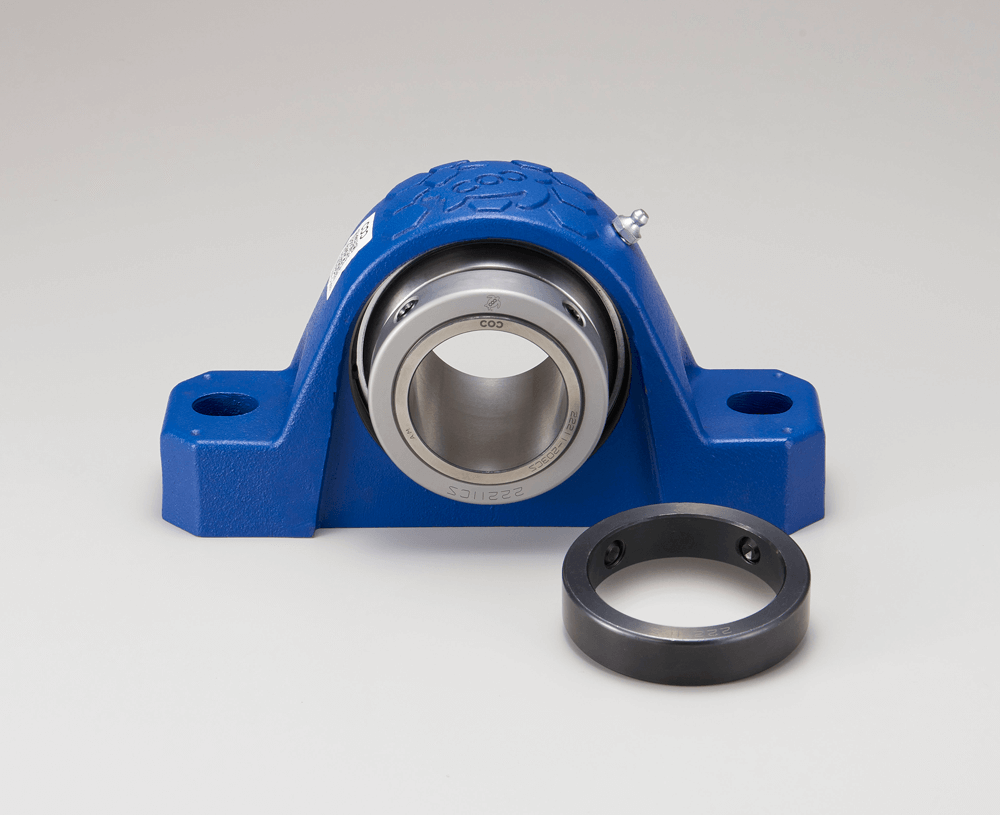

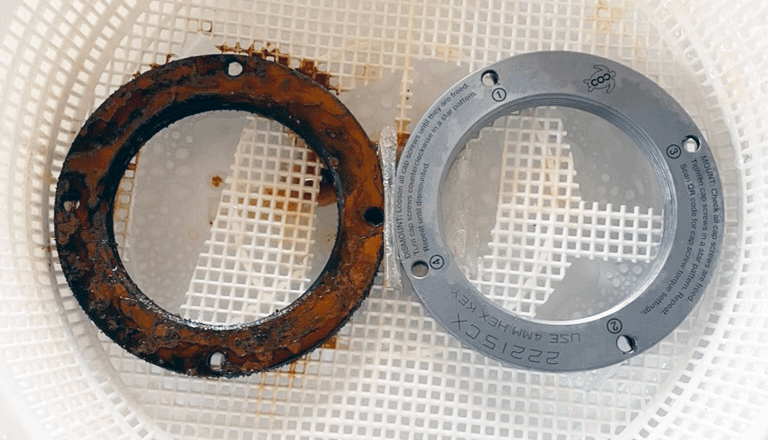

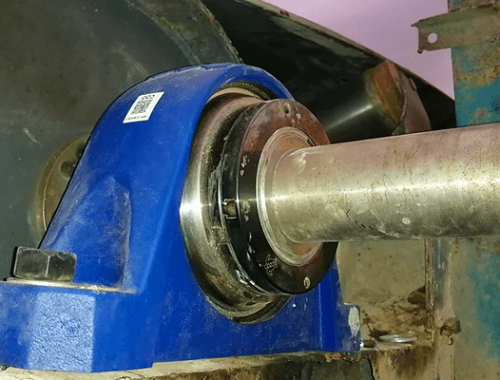

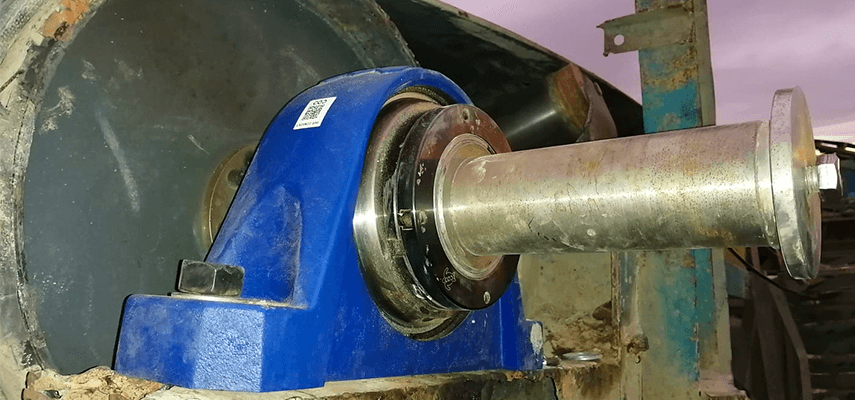

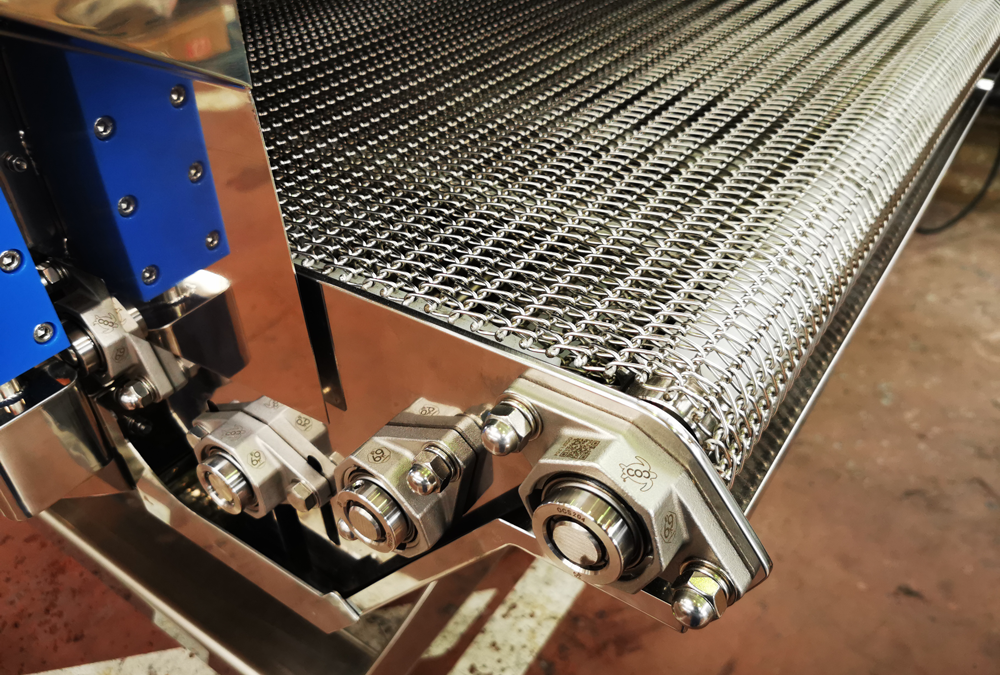

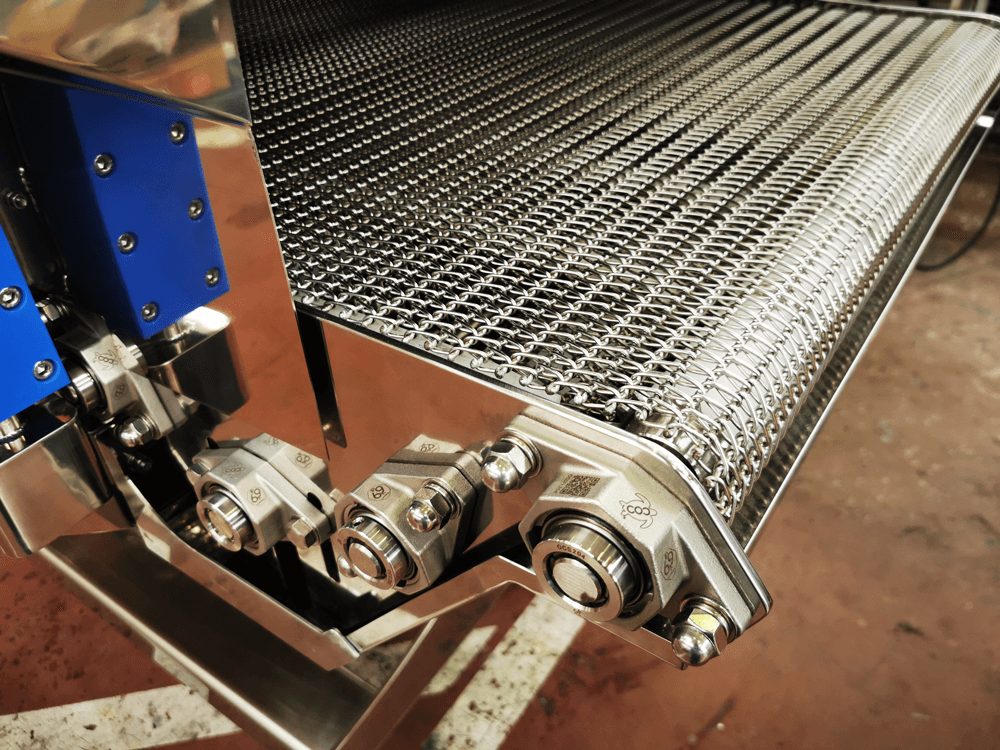

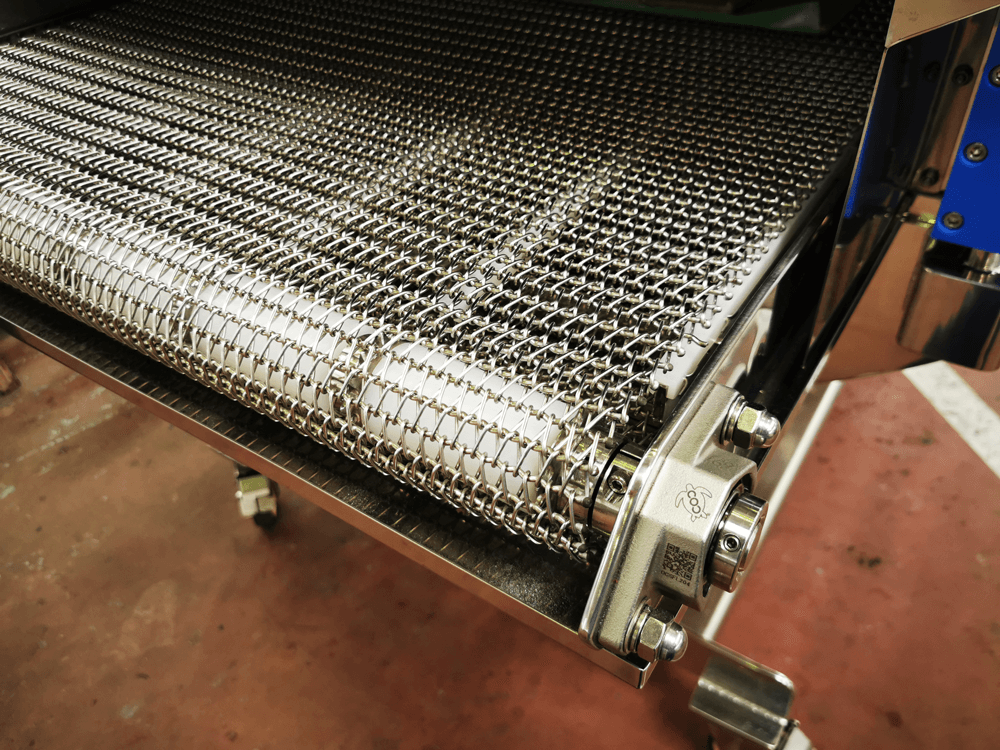

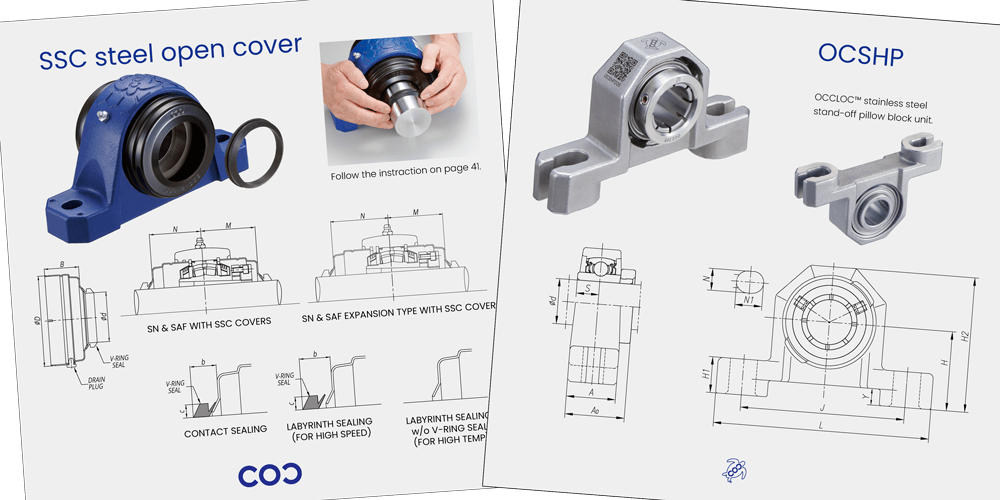

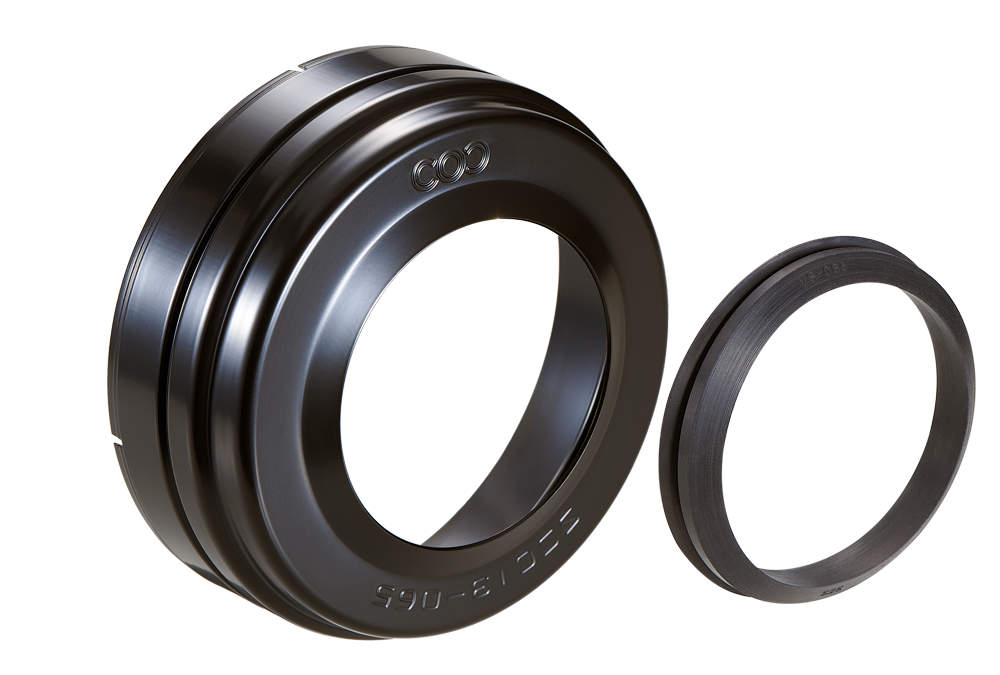

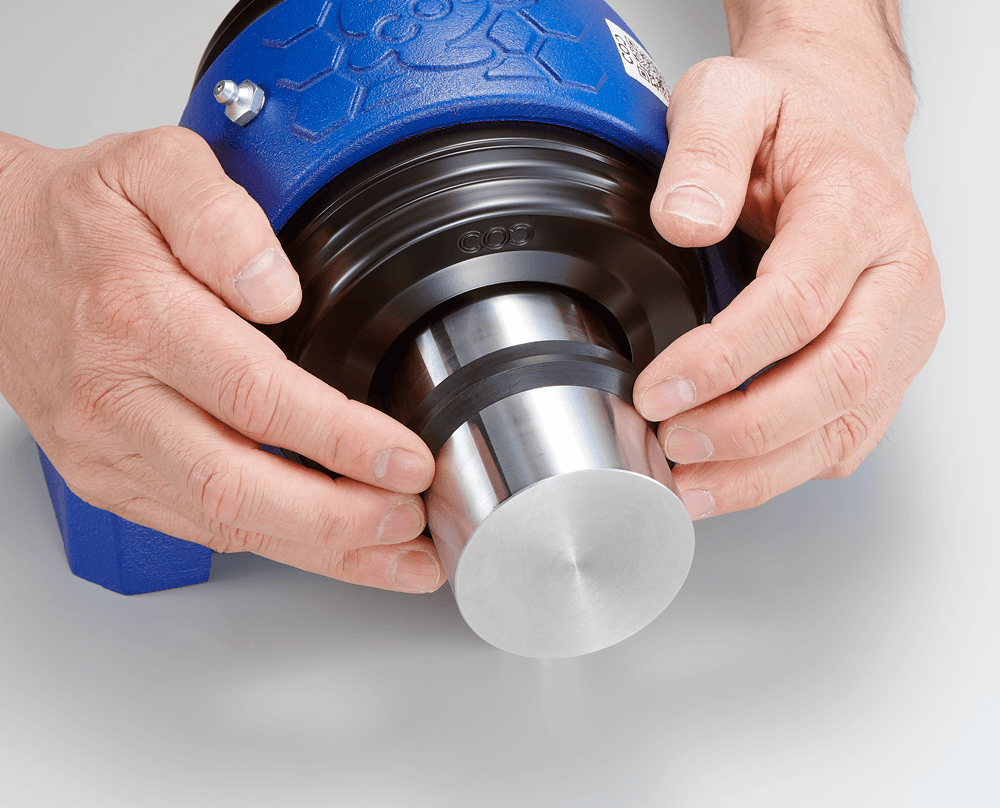

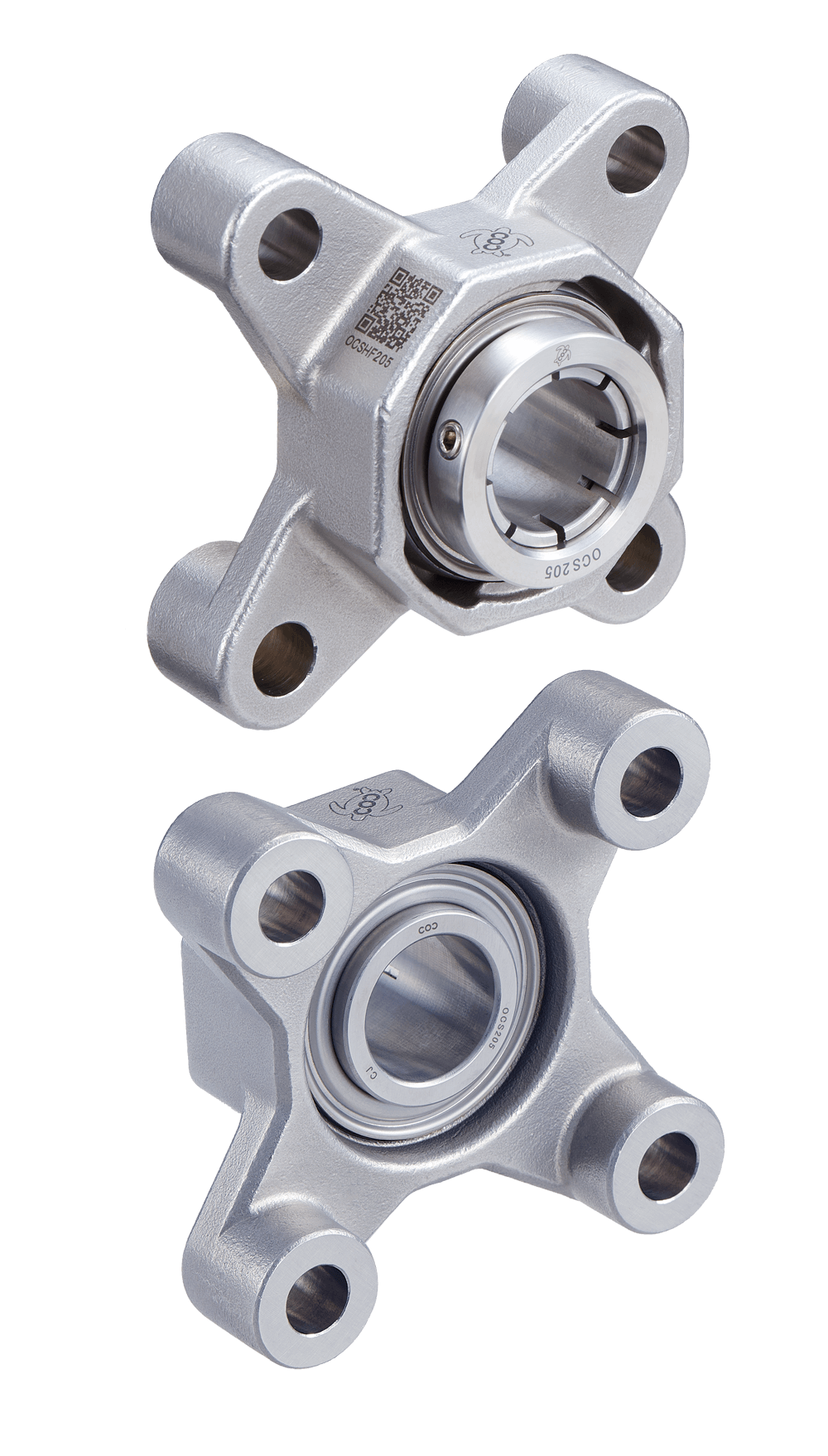

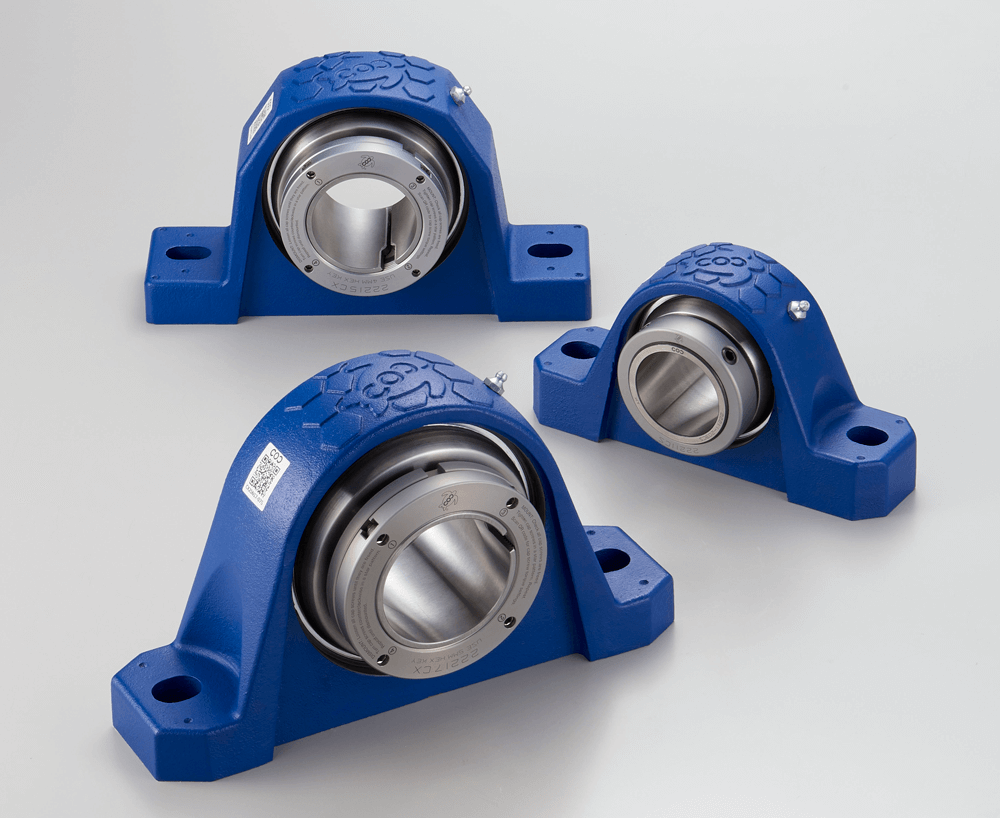

Engineered for longer life.

Brand new designs.

More inventory arriving December 1st. Please visit coc-usa.com for more information.

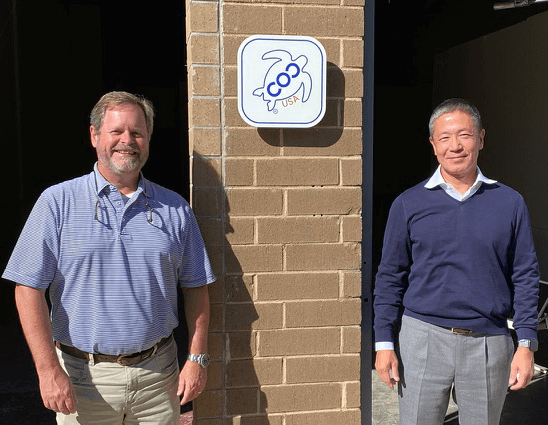

Devin Ware and Eiichi Kobayashi visit the new warehouse location.

COC USA INC.

624 Matthews-Mint Hill Road, Suite C

Matthews, NC 28105 USA

Phone: (888)-706-0059

info@coc-usa.com