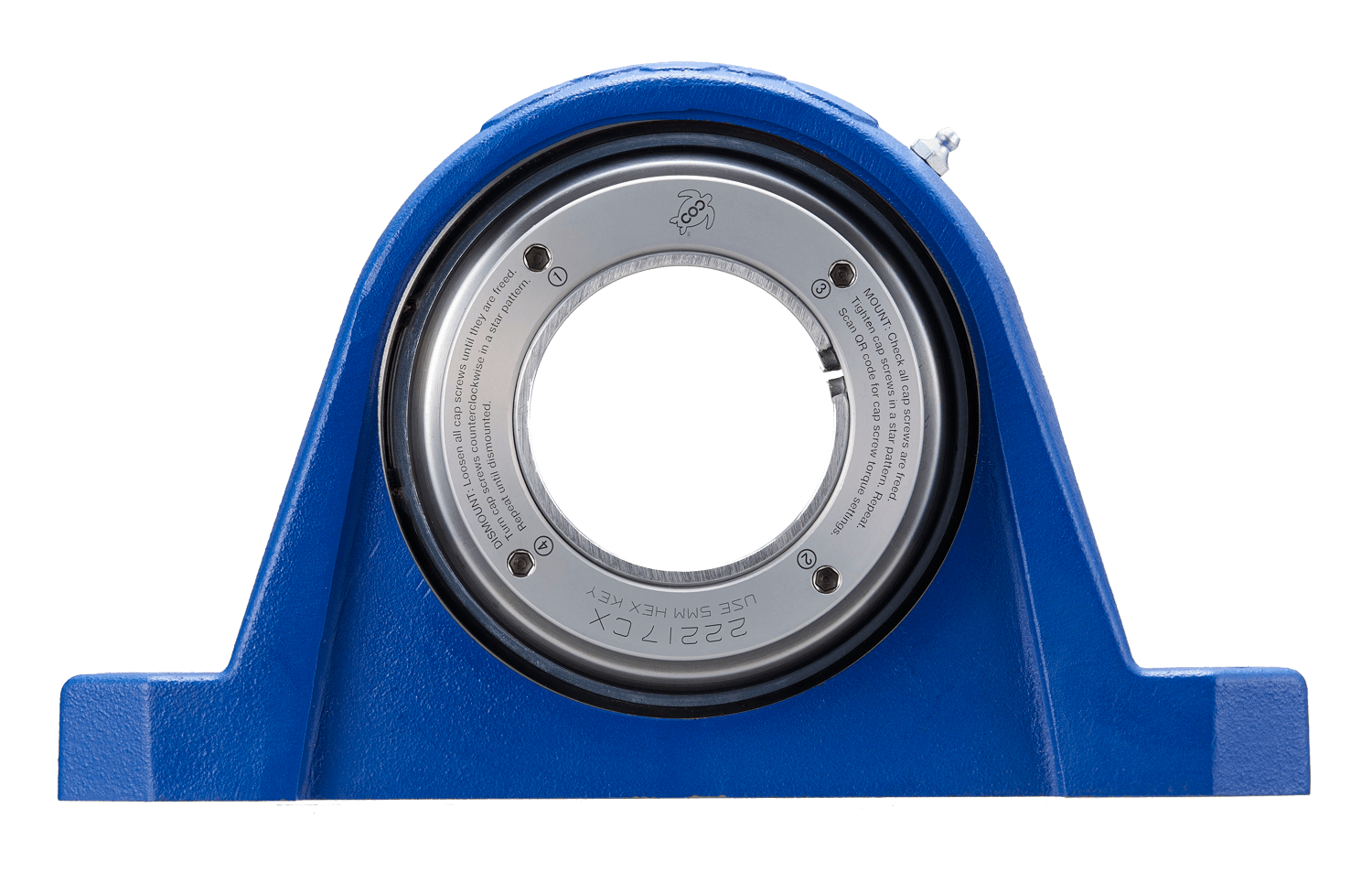

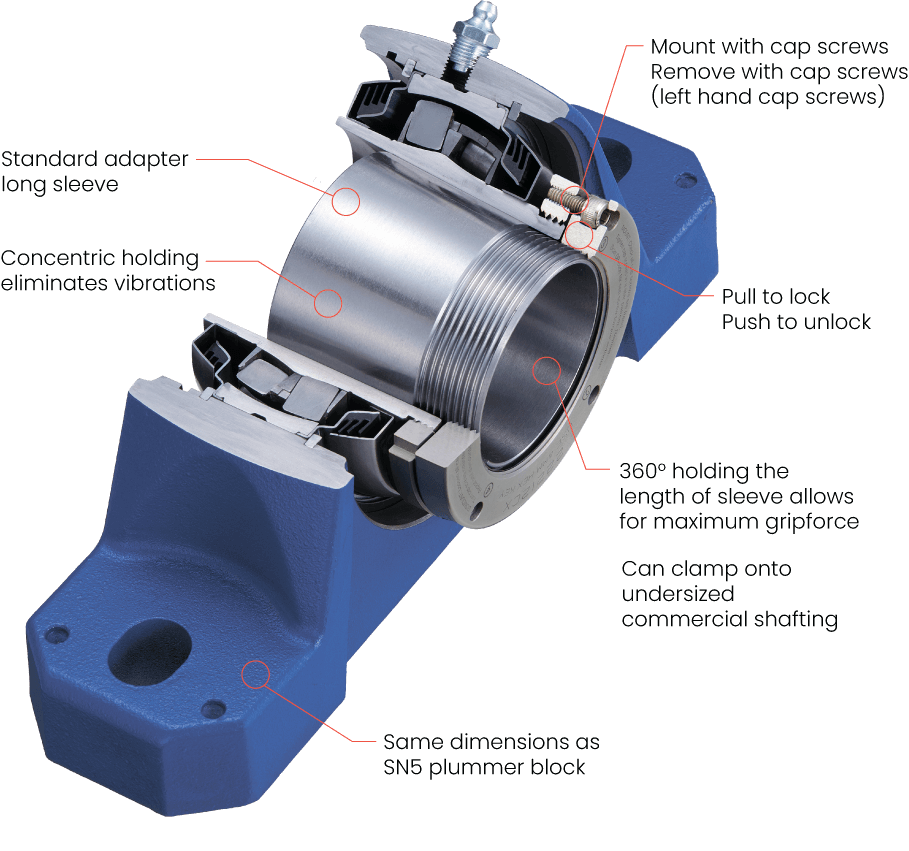

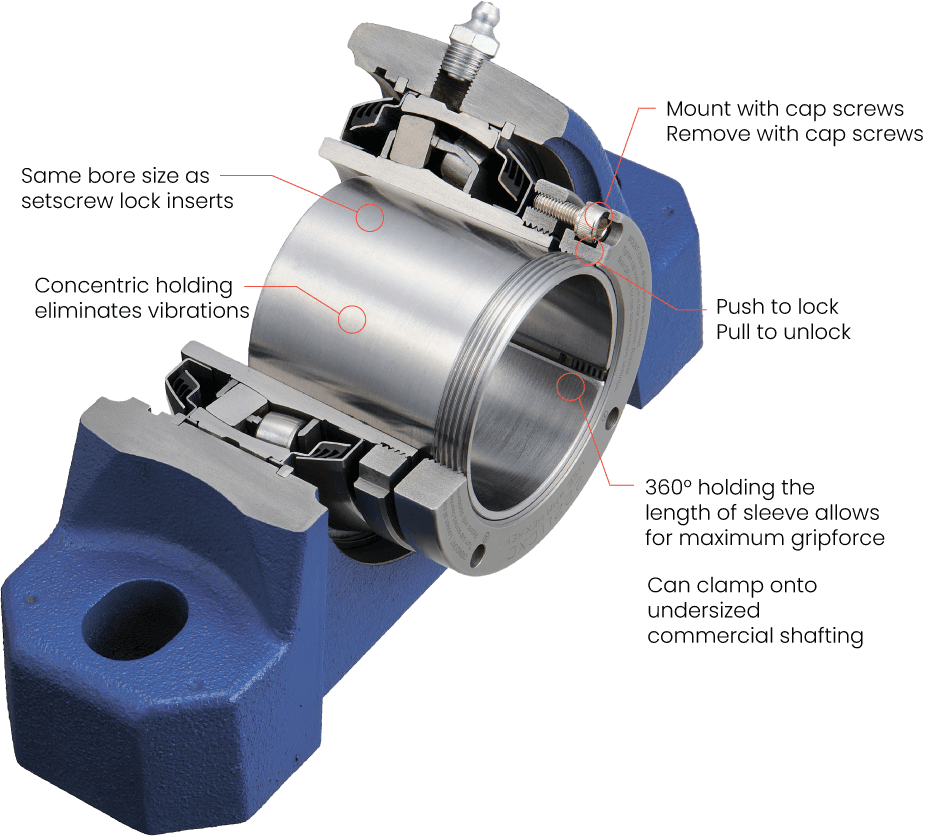

Our patented adapter mount system, CROSSLOC™ utilizes cap screws that allows you to easily mount or dismount our bearing from one side. Tighten cap screws in a star pattern to mount and loosen to dismount. It requires only a hex key. It’s great for the undersized commercial shafts and holds with total shaft contact.

Easy mount & dismount

Vibrating Conveyor

CX2SN20-090L (1480rpm)

CROSSLOC™ is the easiest way to mount and dismount the adapter sleeve.

Just tighten the cap screws as seen below. It requires only a hex key. No feeler gauges are required.

The adapter sleeve is the best way to lock onto the shaft because it doesn’t create any damage on the shaft and holds concentrically even with undersized shafting.

CROSSLOC™ contacts the most shaft area, more than any other locking system. The full contact of the adapter sleeve reduces vibration.

Tightening the cap screws of CROSSLOC is sufficient with significantly less torque compared to locknuts. Unlike traditional locking systems that tighten sleeves with locknuts, CROSSLOC offers a simple method that requires minimal force to move the sleeve during the tightening of the cap screws, eliminating the possibility of installation failures.

Improper installation is one of the major causes of bearing failures. Traditional locknuts require a substantial amount of torque to rotate, and inadequate tightening can lead to shaft slippage or excessive tightening, reducing the clearance within the bearing and potentially shortening the bearing’s lifespan.

CROSSLOC not only reduces costs associated with installation and removal but also enhances uptime.

Recommended Shaft Tolerances

CROSSLOC™ accommodates undersized shafting.

| Shaft Dia. | Setscrew Collar Mount | CROSSLOC Mount |

|---|---|---|

| 1 7/16 - 2 in. | - 0.0015 in. | - 0.003 in. |

| 40 - 55 mm | - 0.038 mm | - 0.076 mm |

| 2 3/16 - 4 in. | - 0.002 in. | - 0.004 in. |

| 60 - 100 mm | - 0.051 mm | - 0.102 mm |

| 4 7/16 - 5 1/2 in. | - 0.003 in. | - 0.005 in. |

| 110 - 140 mm | - 0.076 mm | - 0.127 mm |

One piece housing

& pre lubricated

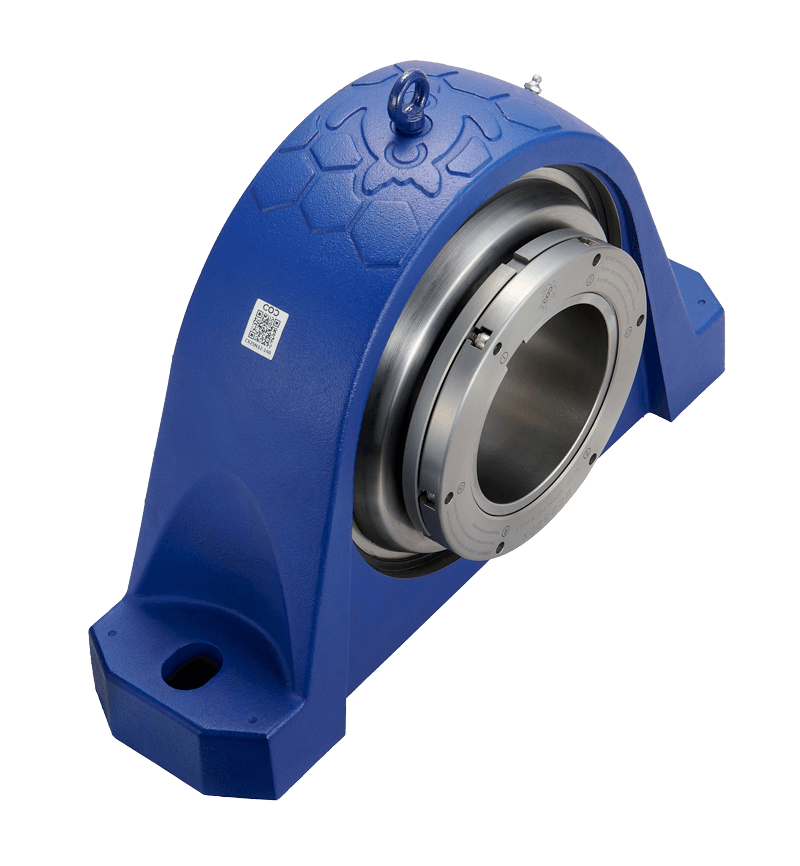

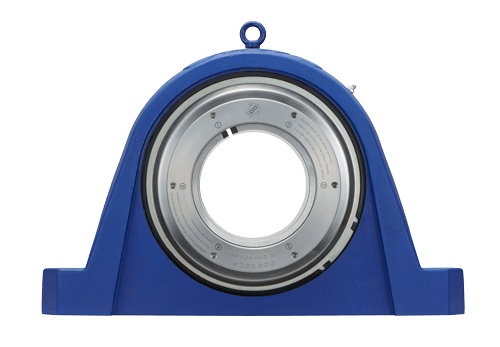

SN

CX2SN

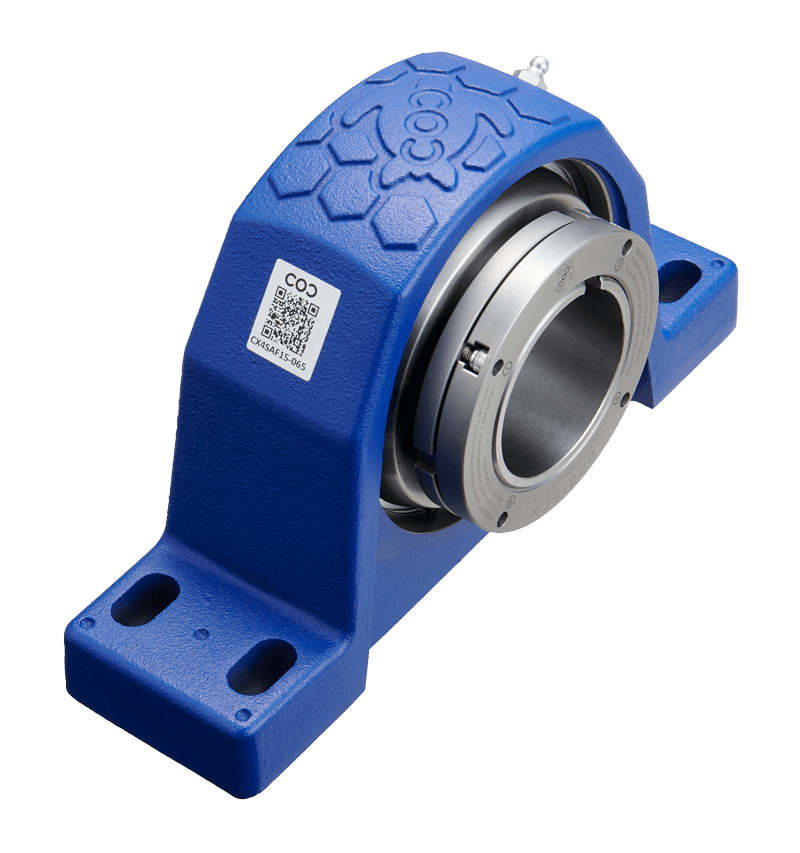

CROSSLOC™ spherical roller bearing with two bolt SN dimension pillow block housing.

CX2SN is 100% compatible with standard SN plummer block products. It is shaft ready, factory assembled and fully lubricated. It can be mounted six times faster than standard SN plummer blocks.

SAF

CROSSLOC™ spherical roller bearing with two and four bolt SAF dimension pillow block housing.

CX2SAF and CX4SAF are 100% compatible with standard SAF plummer block products. It is shaft ready, factory assembled and fully lubricated. It can be mounted six times faster than standard SAF plummer blocks.

CX2SAF

CX4SAF

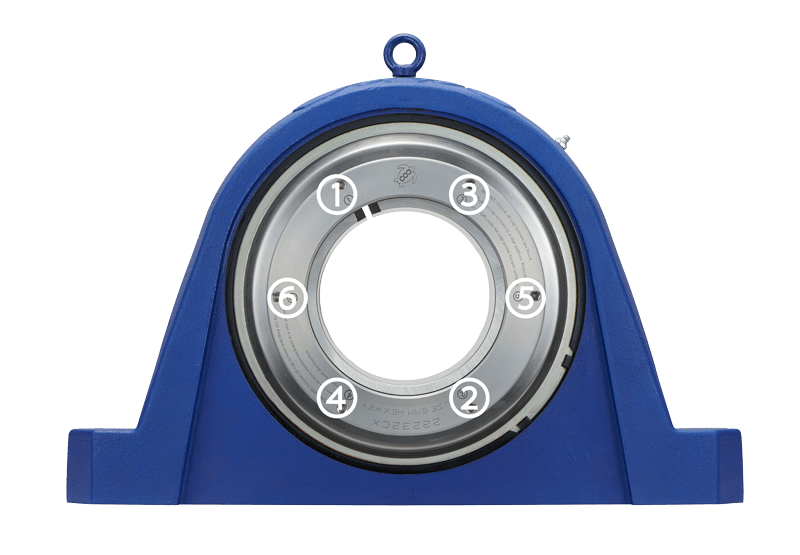

CROSSLOC™ bigger than 125mm and 4-15/16″ bore size have 6 cap screws and their housings have the eye bolt on the top.

360°holding & no damage

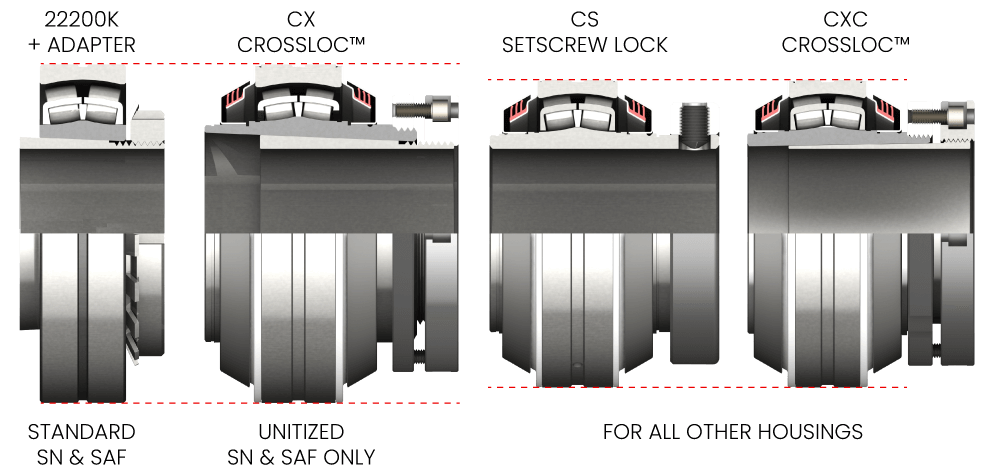

We belive the adapter mount is the best locking system for mounted bearing units. It’s 100% concentric and holds the shaft with the length of the sleeve. Our CROSSLOC™ made the installation of adapter mount easier which is always the issue of the standard adapter mount. So how can we replace the setscrew lock with CROSSLOC™? CROSSLOC™ units are one size bigger than setscrew lock units to accomodate with adapter sleeve. That means the center hegihts and mounting pitches are different. CROSSLOC™ CXC can be the answer for this request.

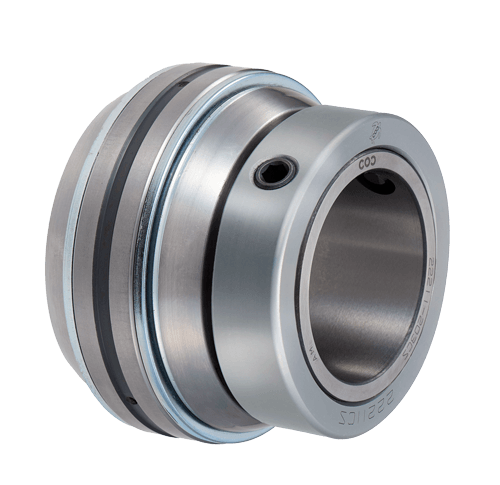

CROSSLOC™ CXC bearing is the same O.D. size version as CS setscrew lock cylindrical bore inserts. It’s one size smaller O.D. than CROSSLOC™ CX inserts for SN & SAF housings. We use our original thinner wall lower angle tapered sleeve for CROSSLOC™ CXC to be compatible with dimensions of CS setscrew lock inserts. The system is very simple as CROSSLOC™ CX as tightening cap screws to lock and loosening cap screws to unlock.

CROSSLOC™ has the sleeve length to contact the shaft concentrically and doesn’t allow vibration and burrs. The cap screws to mount and dismount the locking system is easy for anyone. It doesn’t require any marking on the inner ring or counting how much the lock nut turns.

22200K and CROSSLOC™ CX bearings are the one size bigger O.D. size than CS setscrew lock inserts to accommodate standard adapter sleeve. CROSSLOC™CXC bearing is same size with CS setscrew lock inserts to use the thin wall adapter sleeve with lower taper angle.

COMPARISON BETWEEN CROSSLOC™ AND SET SCREW LOCK

CROSSLOC™ CXC

- Tighten 4 cap screws to lock

- Can use undersized commercial shafting

- Clamp concetrically eliminate vibrations

- Maximum grip force with length of sleeve

- No damage on shafting

SETSCREW LOCK CS

- Tighten 2 set screws to lock

- Should use recommended shaft sizes in catalog

- When the shaft is undersized, unbalanced rotation causes vibrations in high speed applications

- Creates burring on shafting

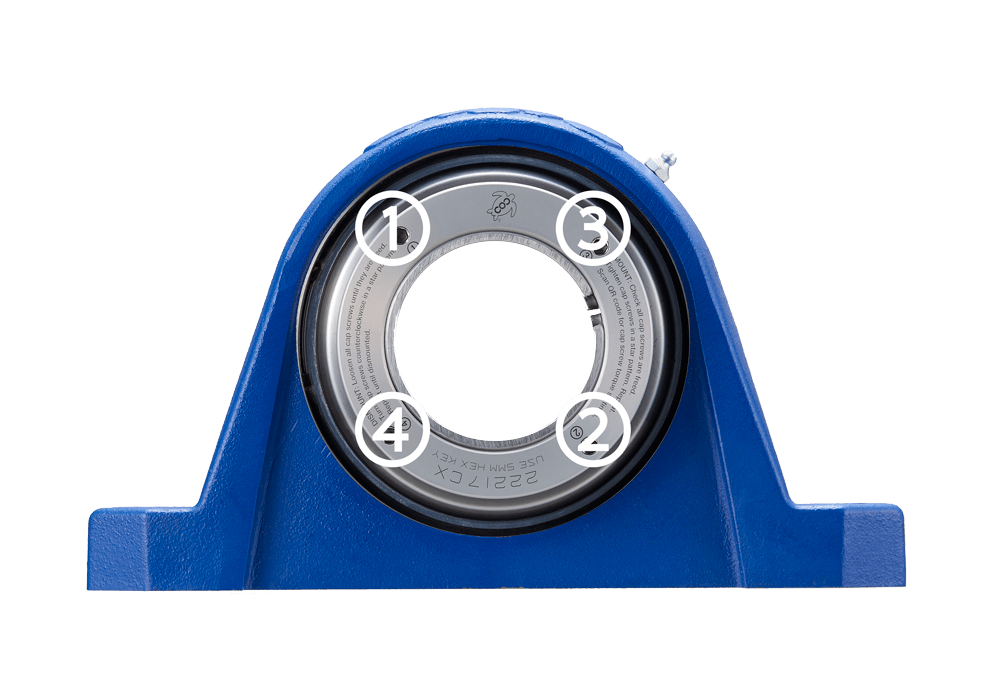

HOW TO LOCK CROSSLOC™

(laser marked instruction on the nut)

Make sure all cap screws are loose.

Tighten cap screws in a star pattern as seen left and repeat several times.

Tighten each cap screw with a torque wrench to the appropriate torque value on the catalog page or scanned page of QR code on the housing.

HOW TO UNLOCK CROSSLOC™

Loosen all cap screws until they are freed.

Turn cap screws counterclockwise in a star pattern and repeat until dismounted.