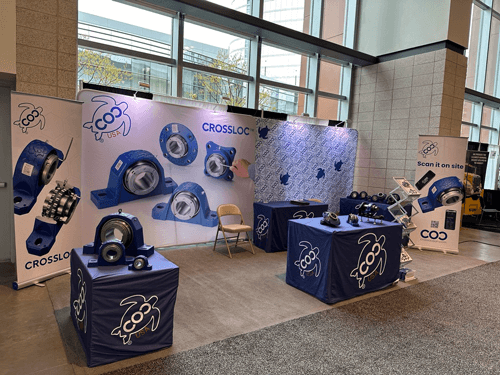

Case Study USA

SOLVING PROBLEMS WITH COC

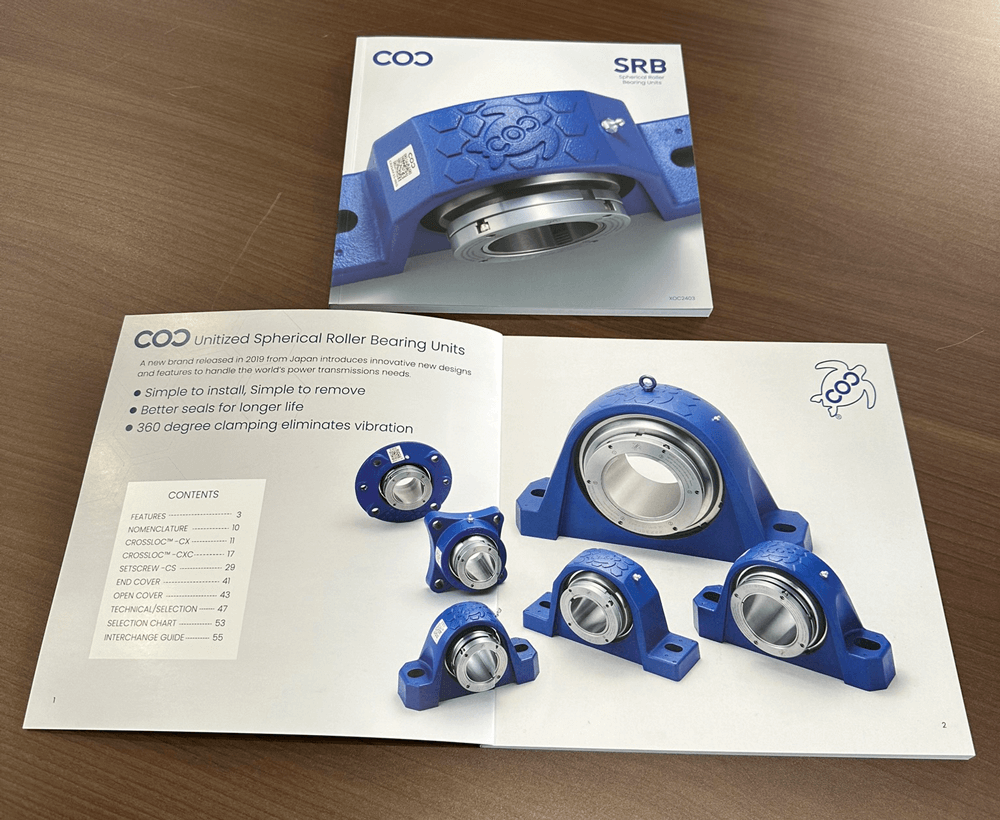

CROSSLOC Spherical Roller Bearings on Dryer Fans

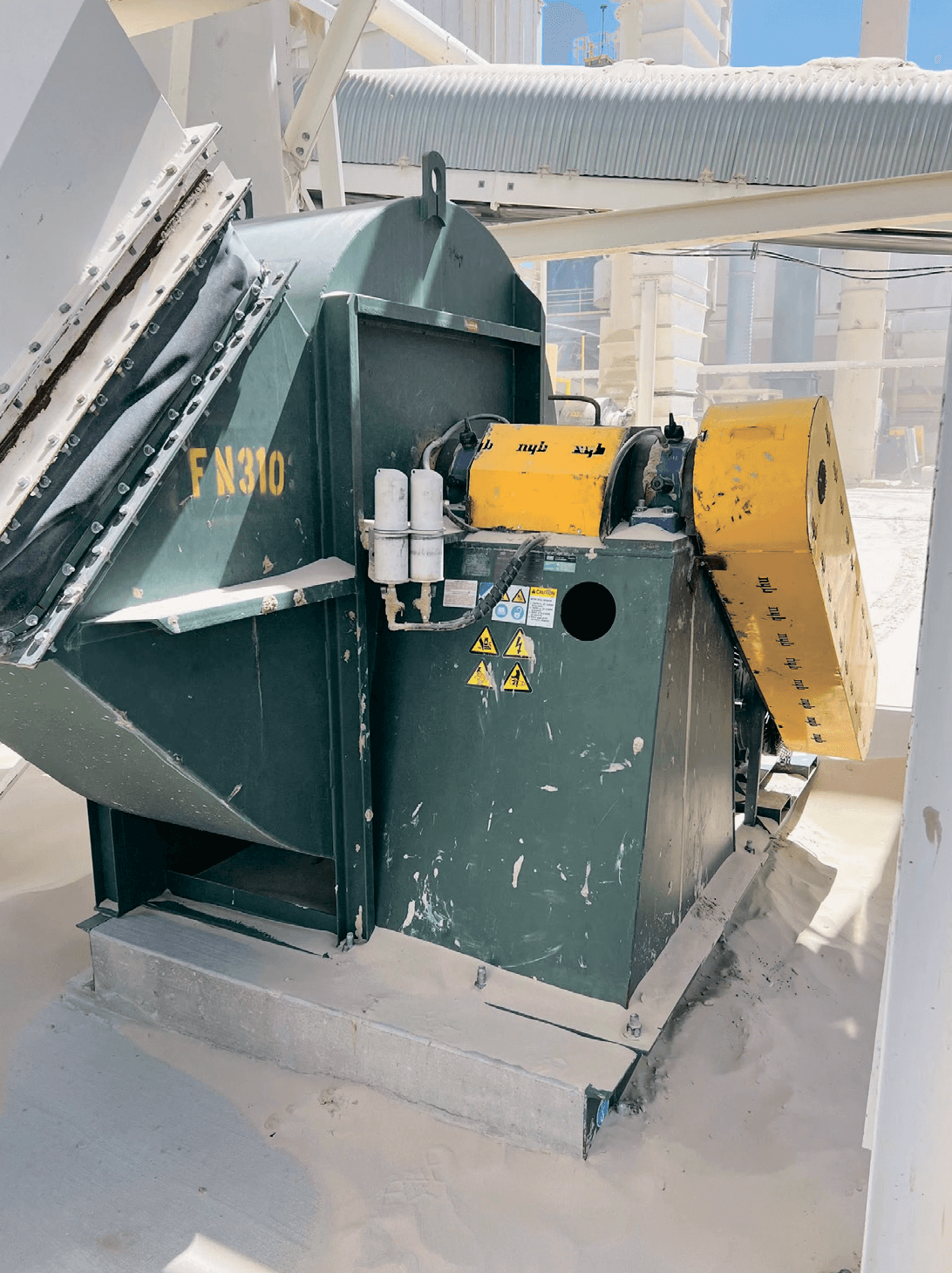

PROBLEM

One of the leading producers of frac sand was having issues with bearing life on their baghouse, combustion, and nuisance fans due to contamination and installation challenges.

SOLUTION

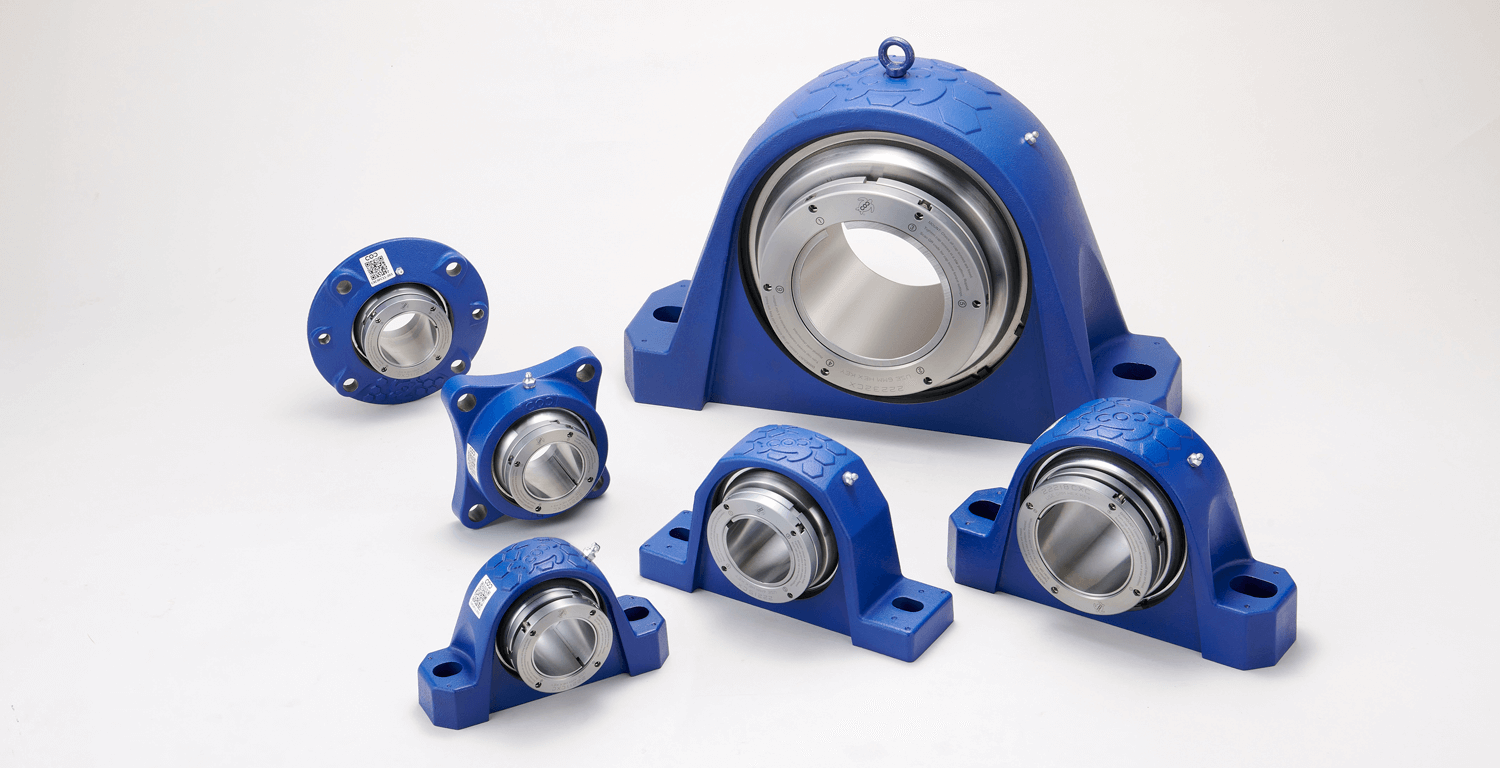

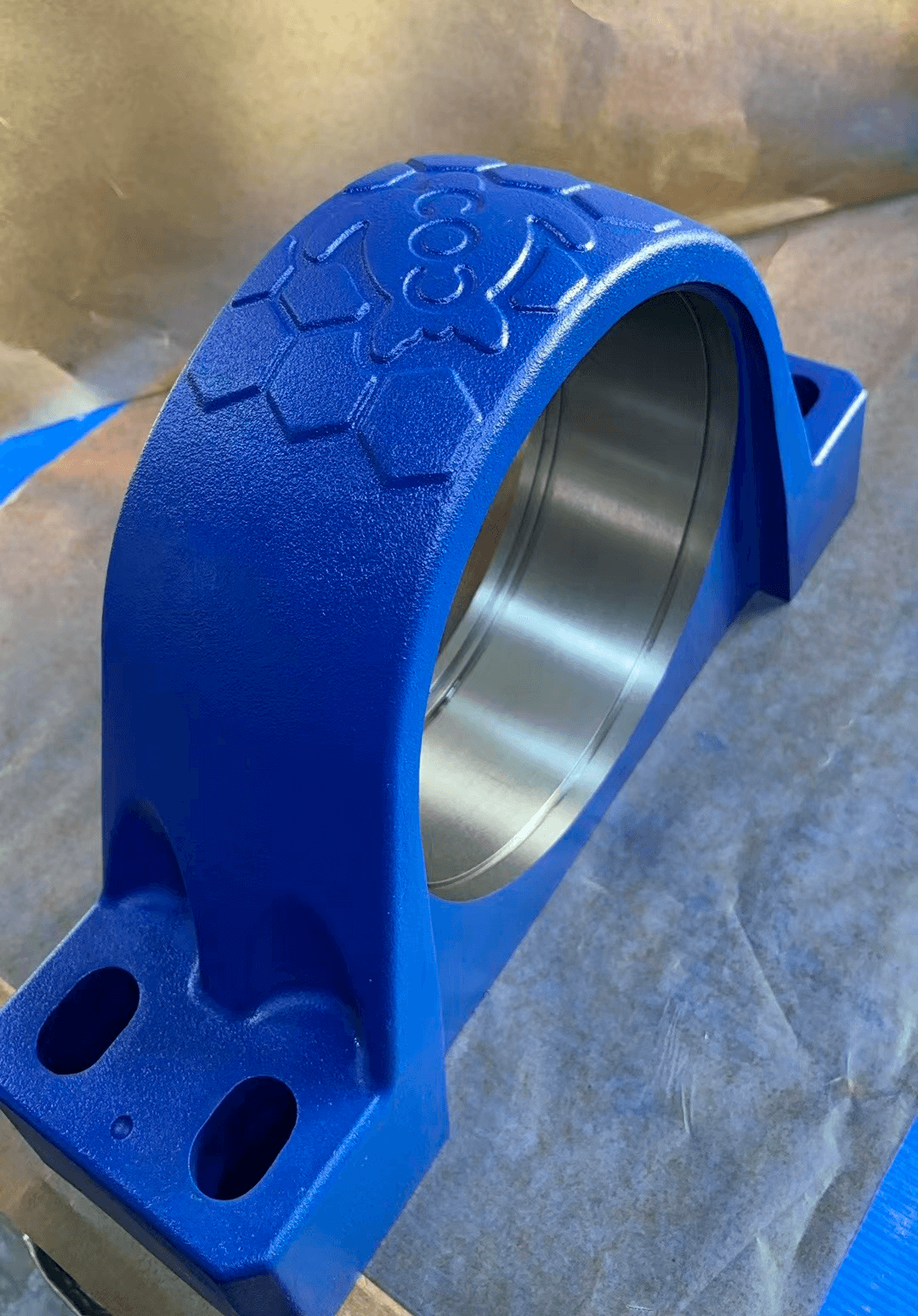

The customer installed two CX4SAF22-315L COC bearings with innovative CROSSLOC adaptor mount systems, extending bearing life by four times. CROSSLOC provides maximum grip force through 360-degree clamping along the length of the sleeve, which eliminates vibration.

KEY PERFORMANCE FEATURES

• Ease of installation: Each COC bearing comes with a QR code that provides all necessary details for installation and maintenance.

• No need to use feeler gauges to set bearing clearances.

• CROSSLOC mount eliminates set screw shaft scoring.

KEY TAKEAWAYS

In most cases, bearings never meet their intended L10 life due to contamination, misalignment, lubrication or poor installation. COC has taken each of these variables into consideration and addressed them in our innovative design.

CONCLUSION

COC spherical roller bearings utilize innovative technology that combats common pitfalls in bearing instrallation, maintainence and repair. Using advances in design, COC provides a superior alternative for today’s maintenance workforce.