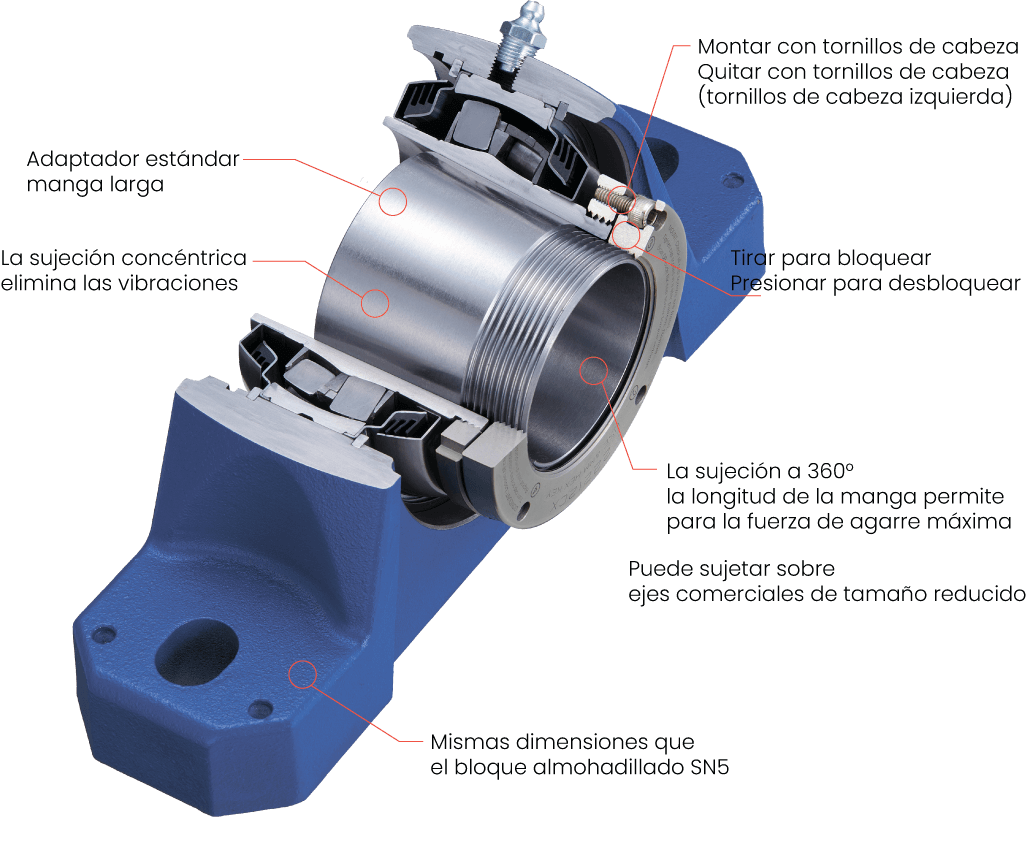

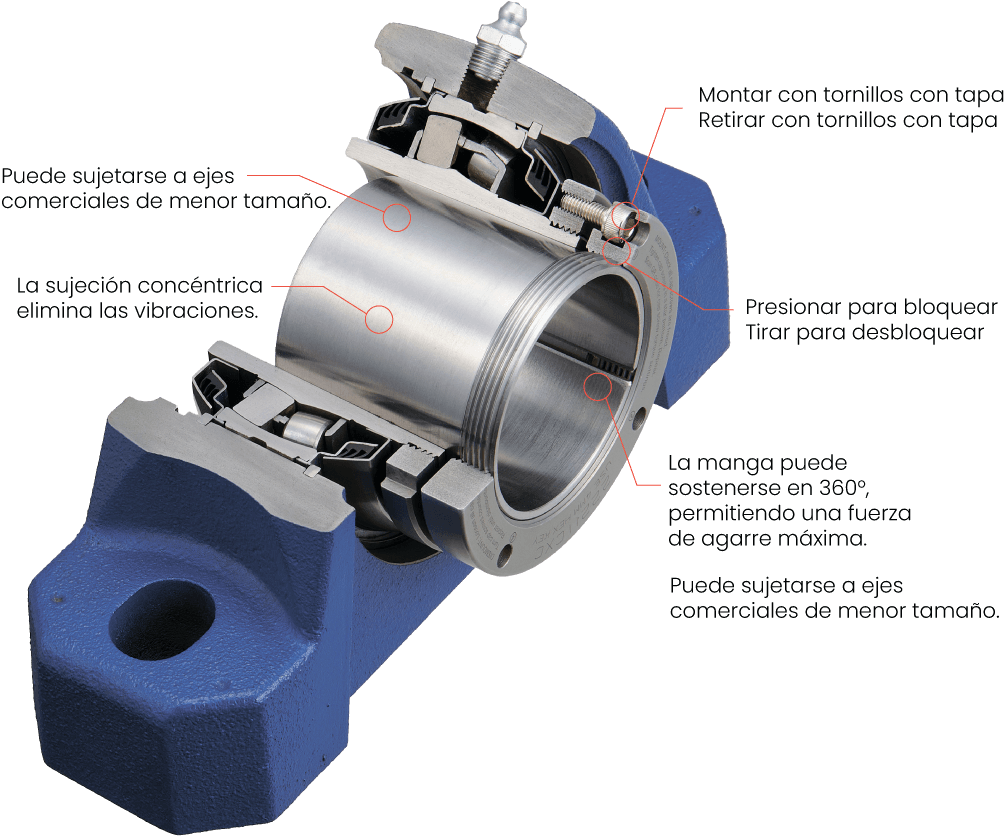

Nuestro sistema de fijación con manguito CROSSLOC™(pendiente de patente) incorpora tornillos axiales que permiten montar y desmontar el rodamiento por un lado. Apriete los tornillos en forma de estrella para montarlo y suéltelos para desmontarlo. Sólo necesita una llave Allen. Es fantástico para los ejes comerciales de tamaño reducido y sujeta mediante un contacto total con el eje.

Montaje y desmontaje fácil

Transportador VibratorioDistribuidor en Sudáfrica

CX2SN20-090L (1480rpm)

CROSSLOC™es la manera más fácil de montar y desmontar el manguito de fijación. Solamente hay que apretar los tornillos como se ve más abajo. Se necesita tan solo una llave Allen y ningún calibre fijo. El manguito es la mejor fijación para el eje porque no lo daña y lo sujeta de manera concéntrica incluso si es de tamaño reducido. El área de contacto entre CROSSLOC™y el eje es mayor que la de cualquier otro sistema de fijación. El contacto total del manguito reduce la vibración.

El apriete de los tornillos de la tapa de CROSSLOC es suficiente con un torque significativamente menor en comparación con las tuercas de bloqueo. A diferencia de los sistemas de bloqueo tradicionales que ajustan las fundas con tuercas de bloqueo, CROSSLOC ofrece un método simple que requiere una fuerza mínima para mover la funda durante el apriete de los tornillos de la tapa, eliminando la posibilidad de fallos en la instalación.

La instalación incorrecta es una de las principales causas de fallas en los rodamientos. Las tuercas de bloqueo tradicionales requieren una cantidad sustancial de torque para girar, y un apriete insuficiente puede provocar el deslizamiento del eje o un apriete excesivo, reduciendo el espacio libre dentro del rodamiento y potencialmente acortando la vida útil del rodamiento.

CROSSLOC no solo reduce los costos asociados con la instalación y la remoción, sino que también mejora el tiempo de funcionamiento.

Tolerancias de eje recomendadas

CROSSLOC™se ajusta a ejes de tamaño reducido.

| Shaft Dia. | Setscrew Collar Mount | CROSSLOC Mount |

|---|---|---|

| 1 7/16 - 2 in. | - 0.0015 in. | - 0.003 in. |

| 40 - 55 mm | - 0.038 mm | - 0.076 mm |

| 2 3/16 - 4 in. | - 0.002 in. | - 0.004 in. |

| 60 - 100 mm | - 0.051 mm | - 0.102 mm |

| 4 7/16 - 5 1/2 in. | - 0.003 in. | - 0.005 in. |

| 110 - 140 mm | - 0.076 mm | - 0.127 mm |

Carcasa de una sola pieza

y pre lubricada

SN

CX2SN

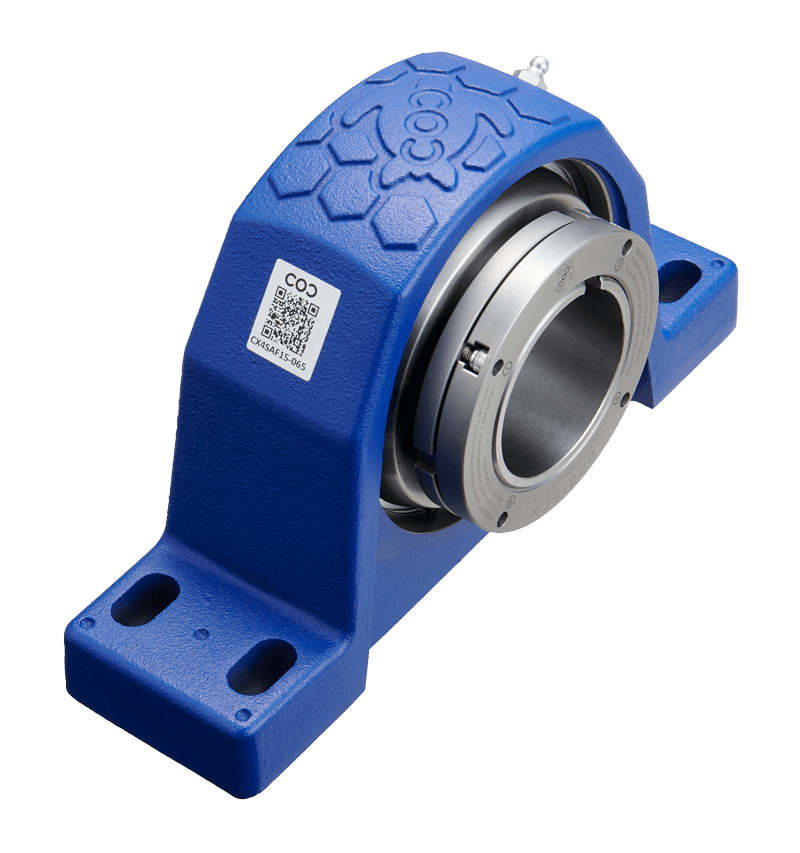

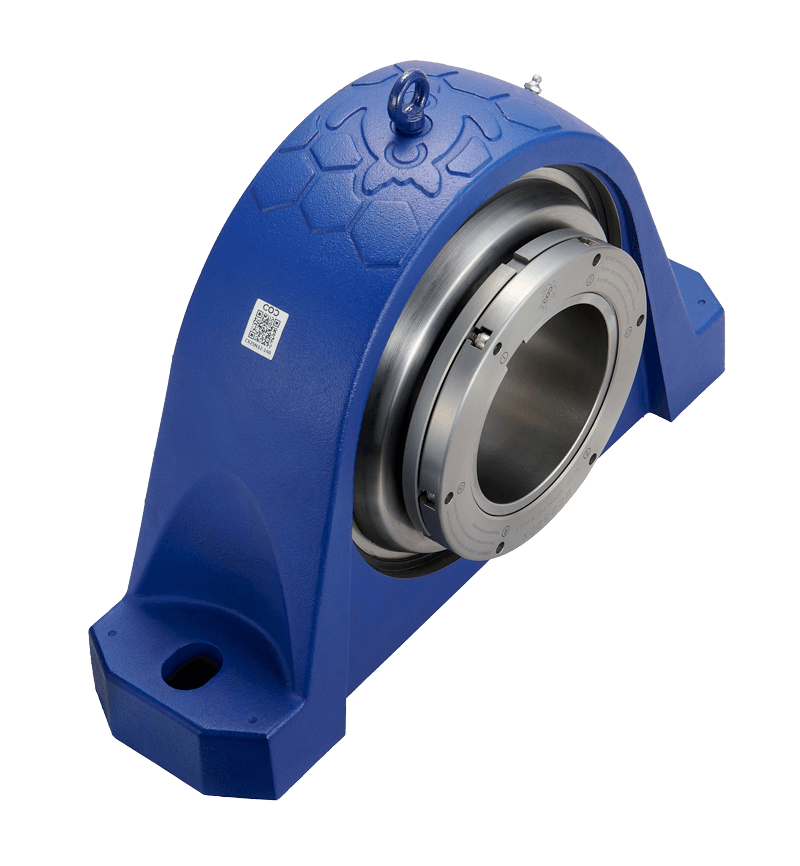

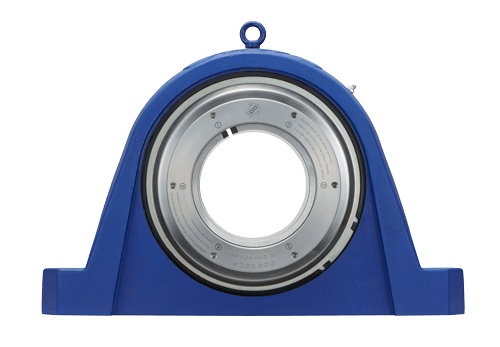

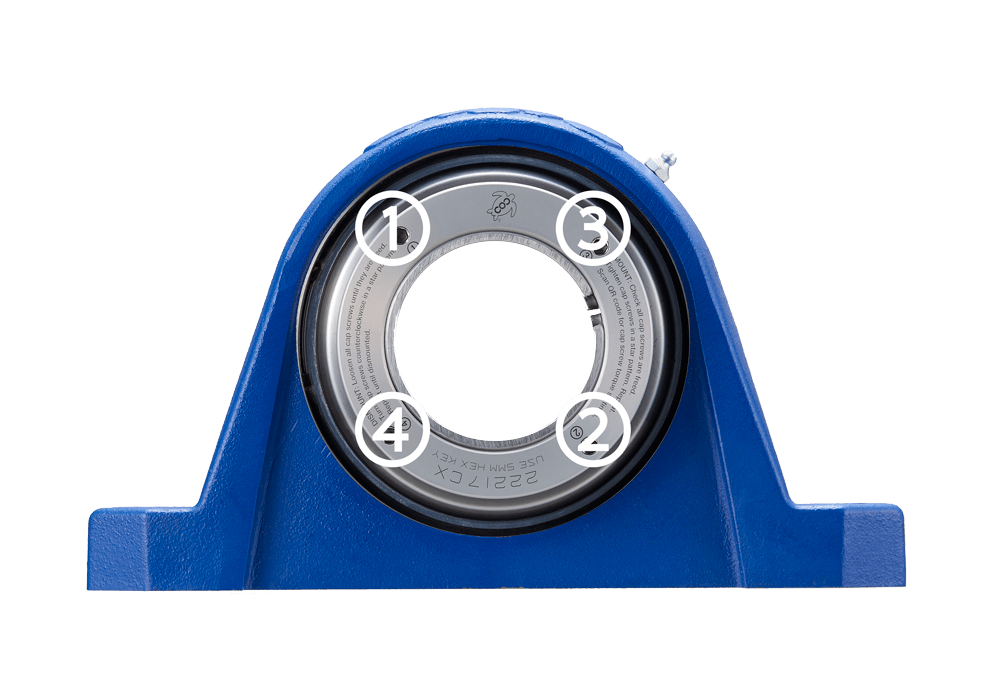

Rodamiento oscilante de rodillos con soporte de apoyo de tamaño SN de dos agujeros y fijación CROSSLOC™. CX2SN es 100% compatible con los productos de los soportes de apoyo SN estándar. Está listo para montar directamente al eje, ensamblado de fábrica y completamente lubricado. Se puede montar seis veces más rápidamente que los soportes de apoyo SN estándar.

SAF

Rodamiento de rodillos esféricos CROSSLOC™ con alojamiento de bloque de almohada de dimensiones SAF de dos y cuatro pernos.

CX2SAF y CX4SAF son 100% compatibles con los productos estándar de bloques de almohada SAF. Está listo para el eje, ensamblado en fábrica y completamente lubricado. Se puede montar seis veces más rápido que los bloques de almohada SAF estándar.

CX2SAF

CX4SAF

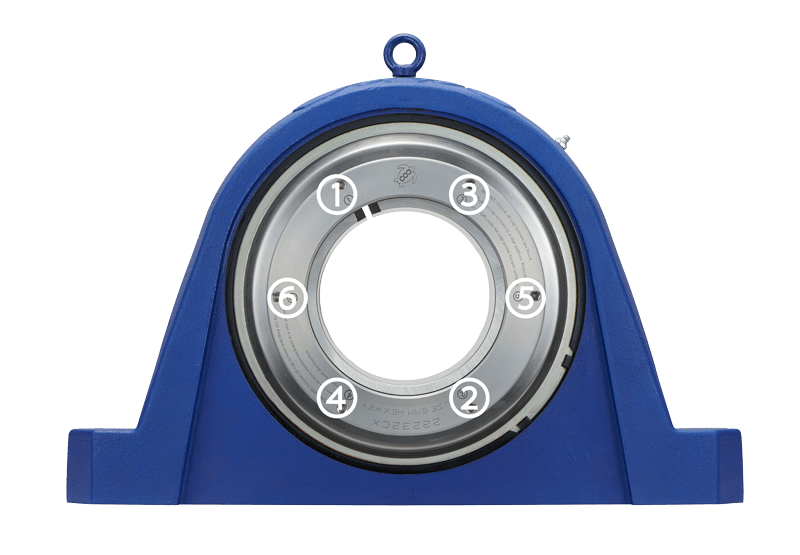

Los rodamientos de rodillos esféricos CROSSLOC™ con un tamaño mayor a 125 mm y un diámetro de orificio de 4-15/16″ tienen 6 tornillos de tapa y sus carcasas tienen el perno de ojo en la parte superior.

Sujeción de 360° y sin daños.

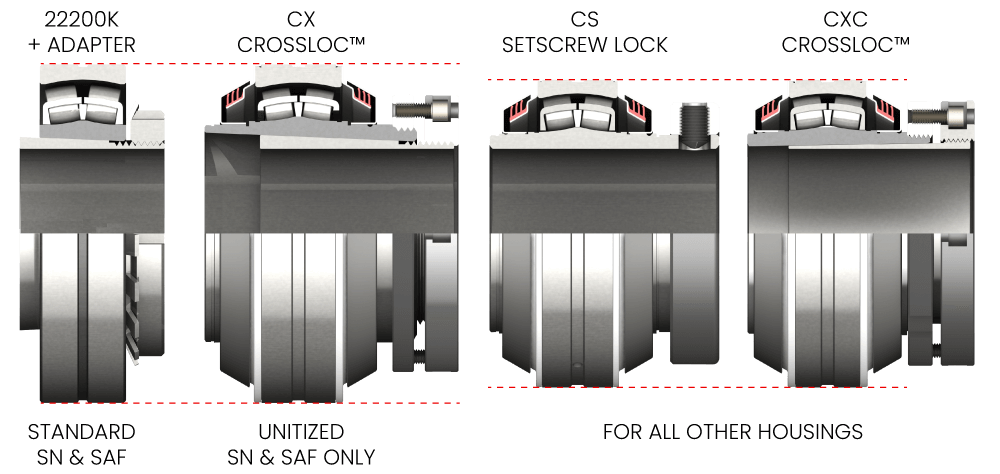

Creemos que el montaje de adaptador es el mejor sistema de bloqueo para unidades de rodamientos montados. Es 100% concéntrico y sostiene el eje con la longitud de la manga. Nuestro CROSSLOC™ facilita la instalación del montaje de adaptador, que siempre es un problema en el montaje de adaptador estándar. ¿Cómo podemos reemplazar el bloqueo de tornillo de ajuste con CROSSLOC™? Las unidades CROSSLOC™ son un tamaño más grande que las unidades de bloqueo de tornillo de ajuste para acomodar la manga del adaptador. Eso significa que las alturas del centro y las dimensiones de montaje son diferentes. CROSSLOC™ CXC puede ser la respuesta a esta solicitud.

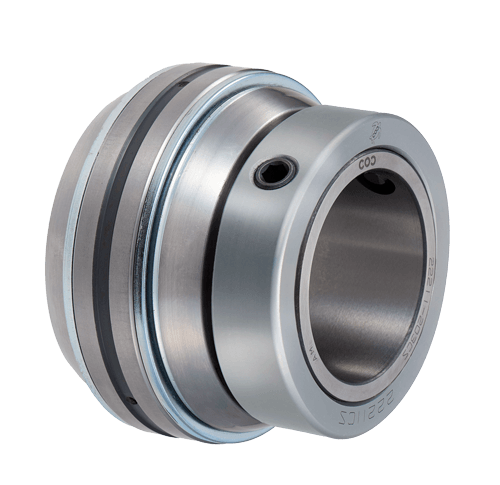

El rodamiento CROSSLOC™ CXC es la versión del mismo tamaño de O.D. que los insertos de diámetro cilíndrico de bloqueo de tornillo de ajuste CS. Es un tamaño más pequeño de O.D. que los insertos CROSSLOC™ CX para alojamientos SN y SAF. Utilizamos nuestra manga cónica de ángulo más bajo de pared más delgada original para CROSSLOC™ CXC para que sea compatible con las dimensiones de los insertos de bloqueo de tornillo de ajuste CS. El sistema es muy simple como CROSSLOC™ CX, apretando los tornillos de tapa para bloquear y aflojando los tornillos de tapa para desbloquear.

CROSSLOC™ tiene la longitud de la manga para contactar el eje concéntricamente y no permite la vibración y las rebabas. Los tornillos de tapa para montar y desmontar el sistema de bloqueo son fáciles para cualquier persona. No requiere ningún marcaje en el anillo interior o contar cuánto gira la tuerca de bloqueo.

Los rodamientos 22200K y CROSSLOC™ CX son de un tamaño más grande de O.D. que los insertos de bloqueo de tornillo de ajuste CS para acomodar la manga del adaptador estándar. El rodamiento CROSSLOC™CXC es del mismo tamaño que los insertos de bloqueo de tornillo de ajuste CS para usar la manga del adaptador de pared delgada con un ángulo de conicidad inferior.

COMPARACIÓN ENTRE CROSSLOC™ Y BLOQUEO DE TORNILLO DE AJUSTE

CROSSLOC™ CXC

- Apriete los 4 tornillos para bloquear.

- Puede usar ejes comerciales de tamaño reducido.

- Abrazadera concéntrica para eliminar vibraciones.

- Máxima fuerza de agarre con longitud de manga.

- No hay daño en el eje.

SETSCREW LOCK CS

- Apriete 2 tornillos de ajuste para bloquear.

- Debería usar los tamaños de eje recomendados en el catálogo.

- Cuando el eje es de tamaño reducido, la rotación desequilibrada provoca vibraciones en aplicaciones de alta velocidad.

- Crea rebabas en el eje.

CÓMO BLOQUEAR CROSSLOC™

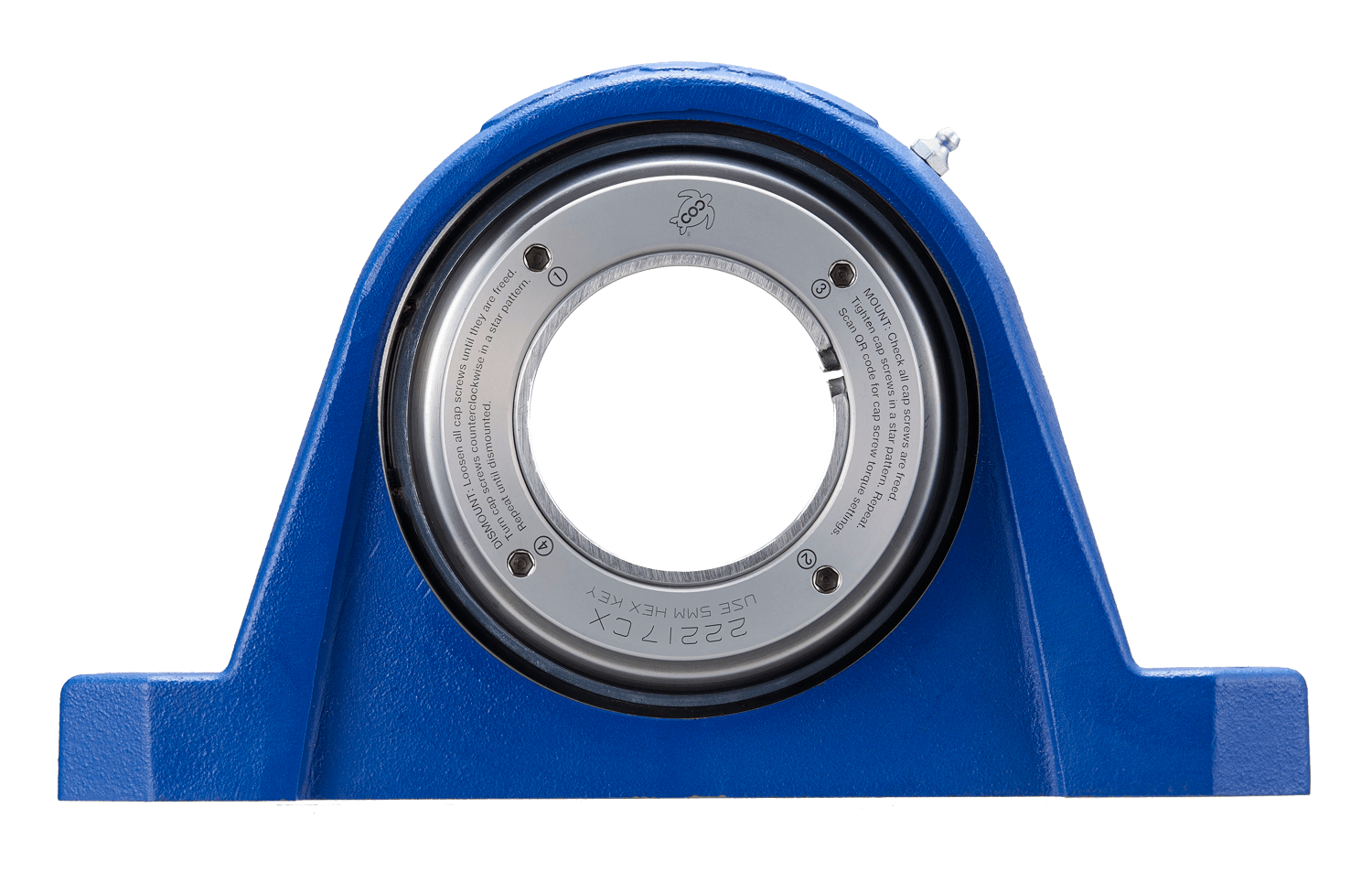

(instrucciones grabadas con láser en la tuerca) Asegúrese de que todos los tornillos de sujeción estén flojos. Apriete los tornillos de sujeción en un patrón estrella como se ve a la izquierda y repita varias veces. Apriete cada tornillo de sujeción con una llave de torque hasta el valor de torque apropiado en la página del catálogo o la página escaneada del código QR en la carcasa.

CÓMO DESBLOQUEAR CROSSLOC™

Afloje todos los tornillos de sujeción hasta que estén libres. Gire los tornillos de sujeción en sentido contrario a las agujas del reloj en un patrón estrella y repita hasta que se desmonte.