Case Study : CX2SN15-065L

Steam Blowers of the textile manufacturer (1900RPM)

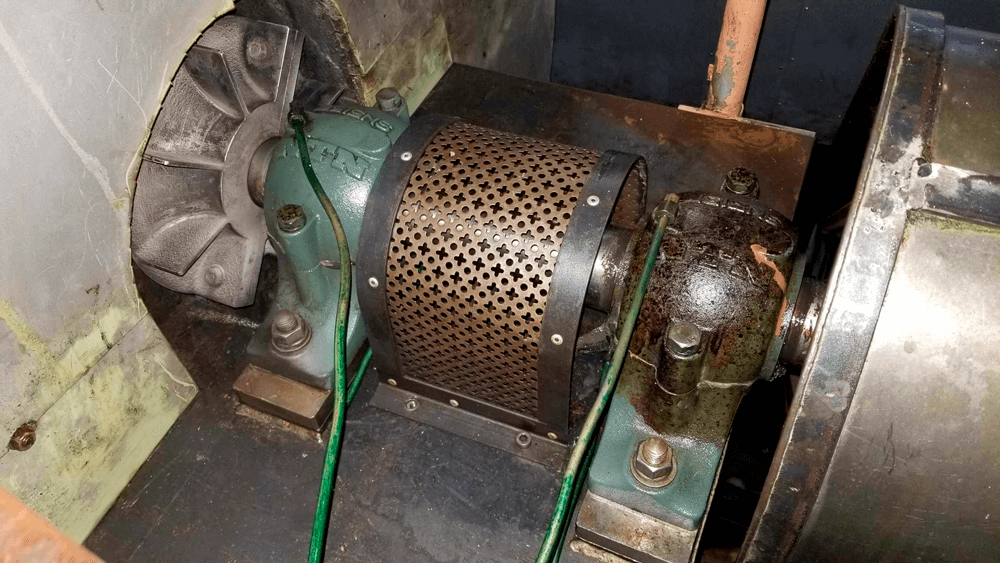

BEFORE

SN515

The surface temperature of the unit rises to 100°C (230° F) within two months of installation. The grease from the unit is changed every two months. The temperature decreases initially after greasing to 80°C (176°F) before starting to rise again.

They cannot change all the grease using a grease gun so they have to take apart the upper part of the housing and clean out all the old grease by hand. This process takes over two hours.

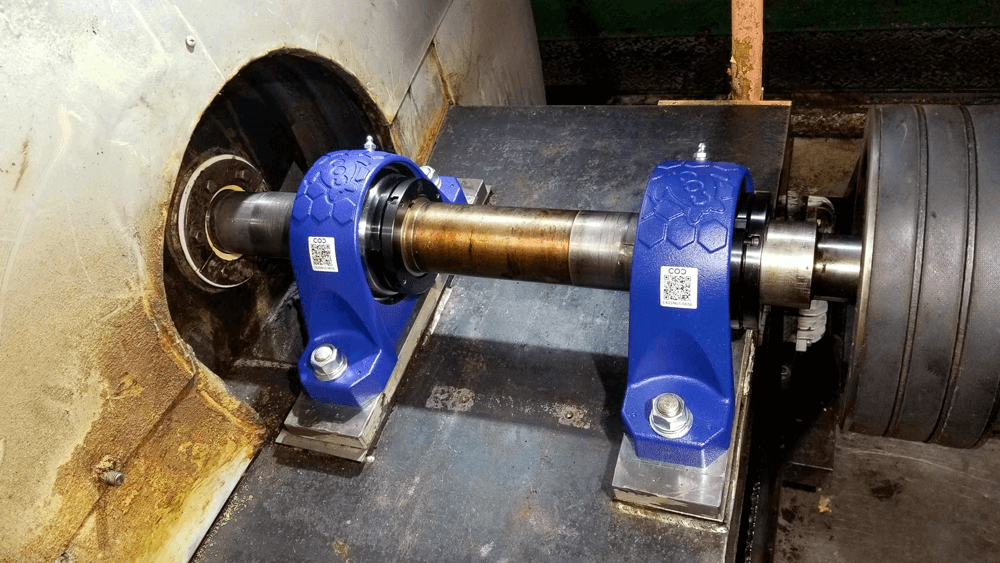

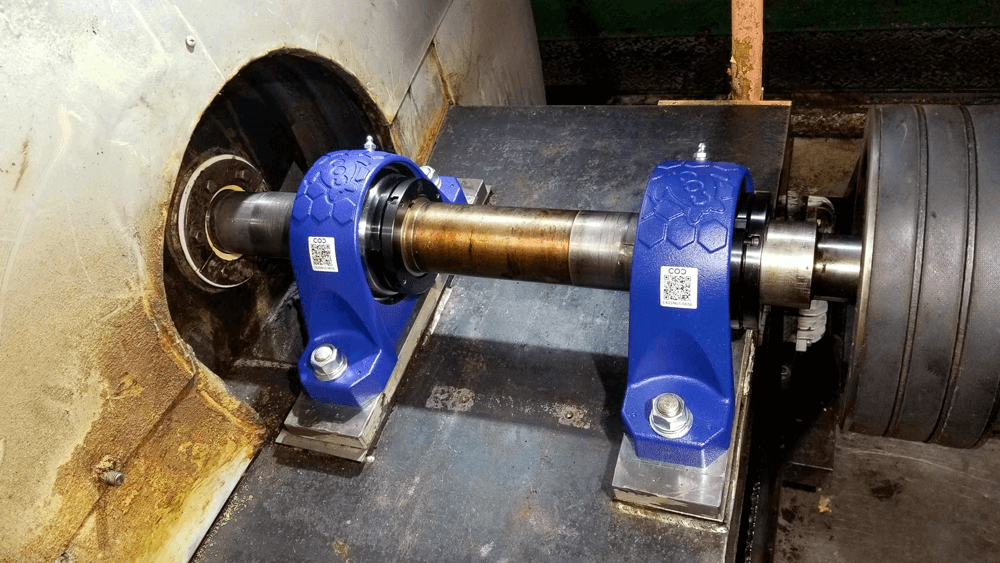

AFTER

CX2SN15-065L

The surface temperature of the units initially went up to 120°C (248°F) and then decreased to 80°C (176° F) after the excess grease was purged within 24 hours. The temperature since then has remained between 65°C (149°F) and 80°C (176°F).

They don’t need to worry about the temperature any more. The COC unit saves money in downtime, labor and the cost of the grease.