Japan Metal Bulletin

Japan Metal Bulletin carries us today.

Japan Metal Bulletin carries us today.

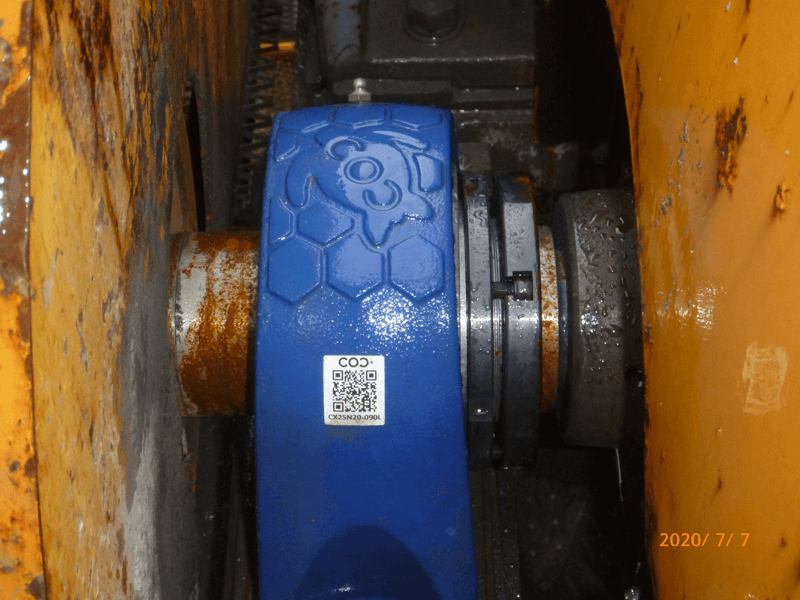

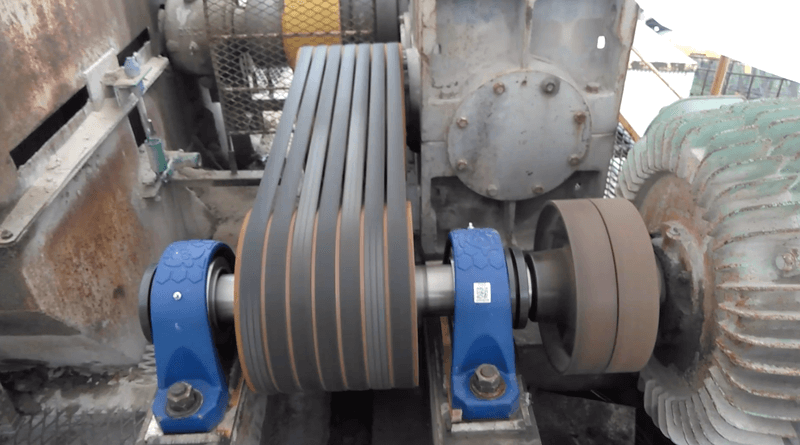

We received this video from a cement company in Hokkaido Japan. This video was taken when they changed their SN520 units to our CX2SN20-090L. Our bearings were recorded before the pulley covers were installed. It’s a loading conveyor application using a 90 mm shaft and rotating at 1450 rpm.

They have been using SN520 bearing units for many years and the temperature of bearings was always a problem. Their regulation is that the temperature of the bearing should be under the air temperature of plus 40°C (104°F). The air temparature during this video was 14°C (57°F) and the SN520 was running at 70°C (158°F) against 54°C (129°F) their maximum temperature regulation. Then they switched to our bearings and the temperature went up to 50°C (122°F) for the first one hour and a half and went down to 26°C (79°F) and remained steady after the excess grease came purged.

Our bearings have been running about a month now and operating temperature remains low. They finally have a solution to a problem that has been plaguing them for years.