What is the difference between CX and CXC?

CX insert bearings have CROSSLOC with standard adapter sleeves and the same outside diameter as 22200 series bearings. CX insert bearings fit only SN and SAF housings. They are one size larger than CS set screw lock and CXC CROSSLOC insert bearings.

CXC insert bearings have CROSSLOC with our original thin adapter sleeves and the same outside diameter as CS inserts. CXC and CS insert bearings fit only the S-2000 and Type E dimension housings.

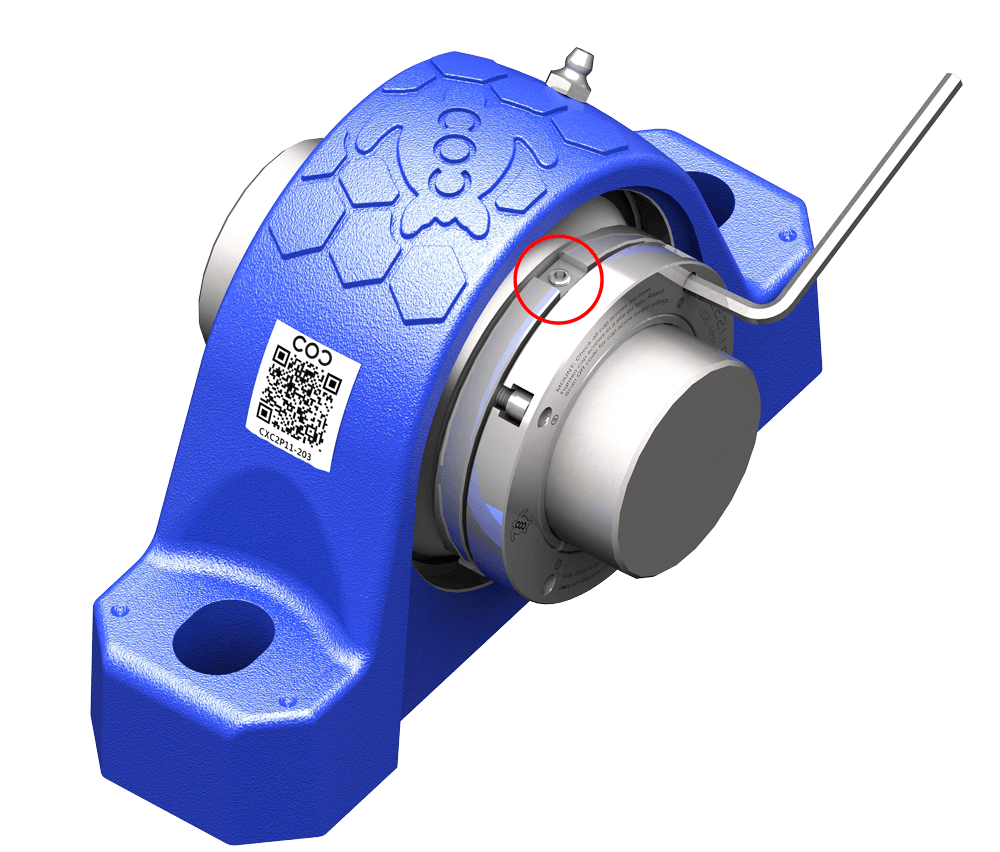

I disassembled CROSSLOC. What is the gap between the nuts to reset?

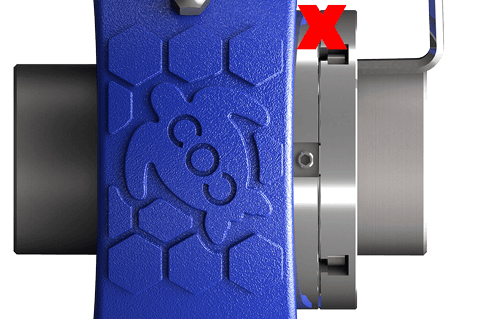

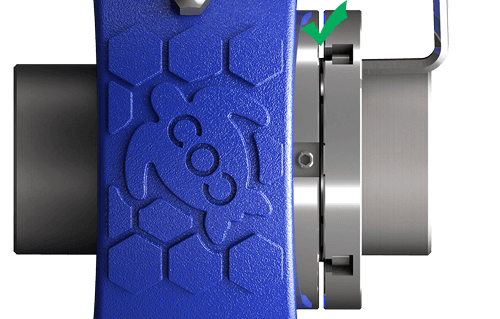

CX CROSSLOC INSERTS

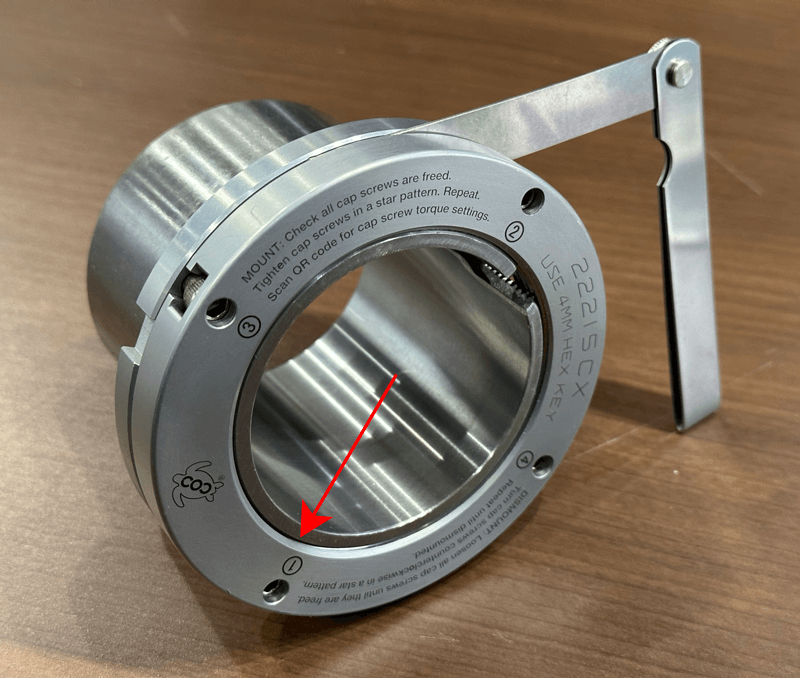

Use feeler gauges to set the clearance between inner and outer locking nuts of CX inserts. See below chart for those dimensions.

If the locking nuts become difficult to turn when tightening to the inner ring, make sure all cap screws are freed. The adapter sleeve should be at the inside edge of the chamfer of locknut. CX CROSSLOC pulls the adapter sleeve through the bore to lock the bearing to shaft.

| CX | CAP SCREWS (metric) | NUTS CLEARANCE (mm) |

|---|---|---|

| 22210CX-22215CX | M5 X 12 (Left hand) | 0.5 (0, +0.4) |

| 22216CX-22219CX | M6 X 14 (Left hand) | 0.5 (0, +0.4) |

| 22220CX-22232CX | M8 X 16 (Left hand) | 0.8 (0, +0.5) |

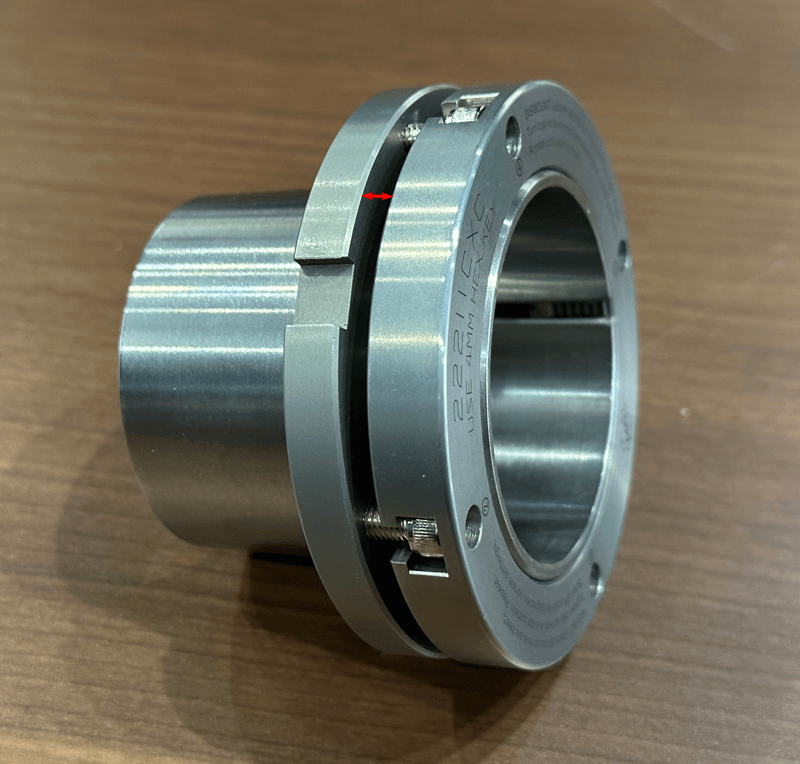

CXC CROSSLOC INSERTS

The inner and outer locknuts should have a clearance of between 4.8 and 5.8mm depending on the size of the insert bearings. See the chart below for a list of those dimensions.

If the locking nuts become difficult to turn when tightening to the inner ring, make sure all cap screws are freed. CXC CROSSLOC pushes the adapter sleeve into the bore to lock bearing to shaft.

| CXC | CAP SCREWS (metric) | NUTS CLEARANCE (mm) |

|---|---|---|

| 22208CXC-22215CXC | M5 X 12 | 4.8 (0, +0.2) |

| 22216CXC-22219CXC | M6 X 14 | 5.3 (0, +0.2) |

| 22220CXC-22222CXC | M8 X 16 | 5.8 (0, +0.2) |

What is the temperature range of SRB bearings?

The limiting factor is the NBR triple lip seal inside the bearing, which is rated from -20℃(-4°F) to +110℃(+230°F). The labyrinth seals without NBR lips can be used from -20℃(-4°F) to +160℃(+320°F), and up to +200℃(+392°F) for short period.

How can I find the serial number in the QR code on housing?

Scan the QR code using a bar code reader app instead of the camera. The serial number should be displayed after the underscore following the web link.

What is the purpose of the setscrew on the inner nut of CXC CROSSLOC units?

When the shaft rotates rapidly counterclockwise, CXC CROSSLOC nuts are at increased risk of loosening and pulling the sleeve. For safety, ensure the setscrew is tightened firmly before use. The factory has not tightened it fully to avoid obstructing the shaft during installation.

Conversely, when removing the CXC CROSSLOC unit, please loosen this setscrew first. Since the setscrew presses against the inner ring, the sleeve may sometimes be difficult to move.

I tightened the cap screws on the CXC CROSSLOC to the recommended torque, but it failed to grip the shaft properly and the nut came loose.

All cap screws must be fully tightened to the recommended torque, and there should be a visible gap between the two nuts. If the outer nut contacts the inner nut during tightening and there’s no gap, it indicates the shaft is too small. In that case, loosen the cap screws to return the nut to its original position, then slightly shift the sleeve further inward by loosening it to reduce the bore size.

Please refer to the QR code link on the housing and see step #5 in the MOUNT instructions.