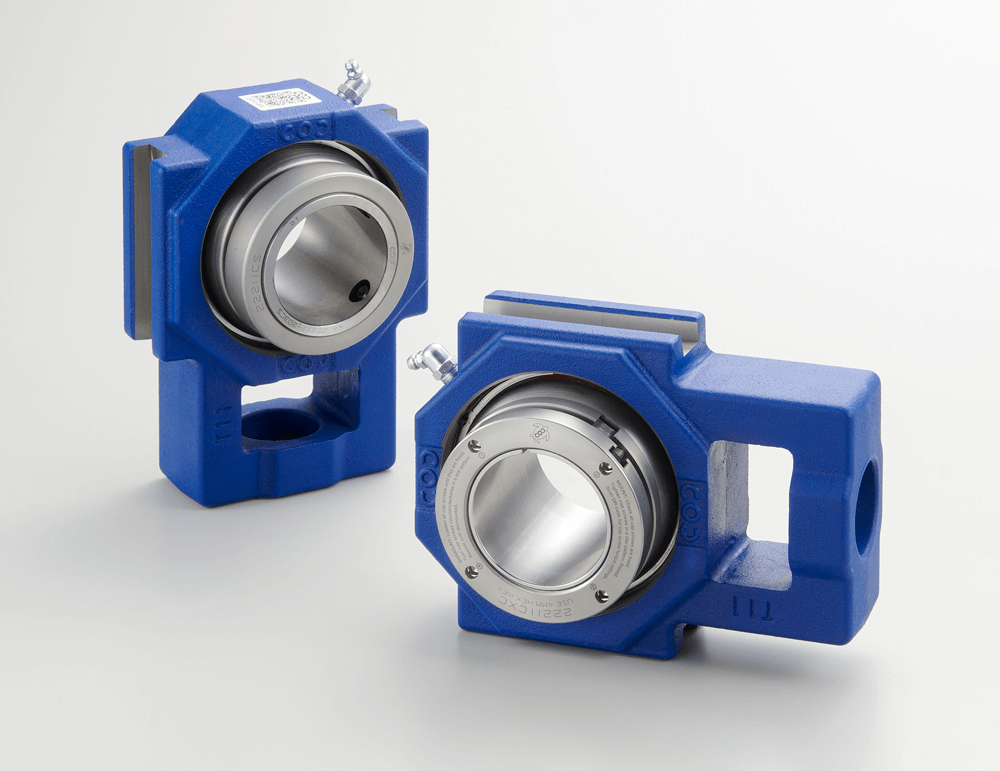

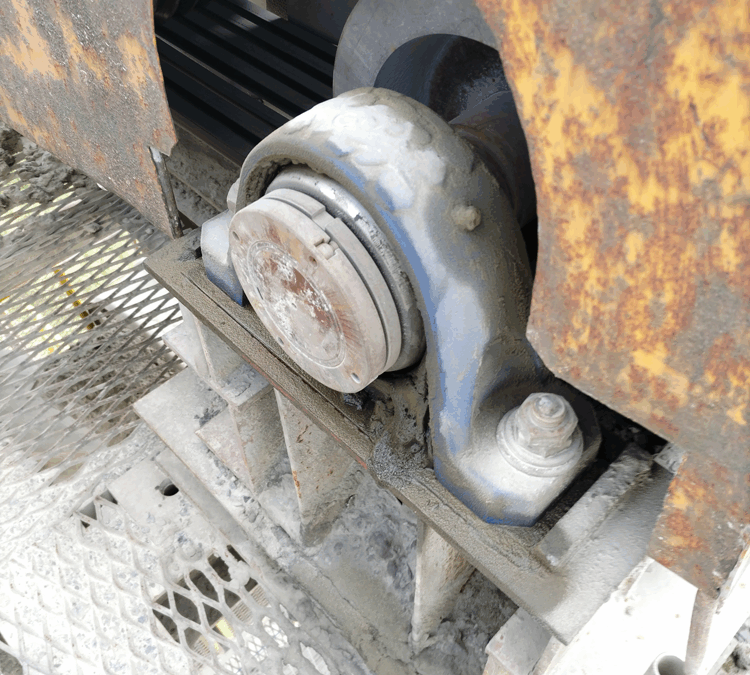

CX2SN20-090L DOPO 5 ANNI

Questo è un aggiornamento al nostro post del 25 maggio 2023.

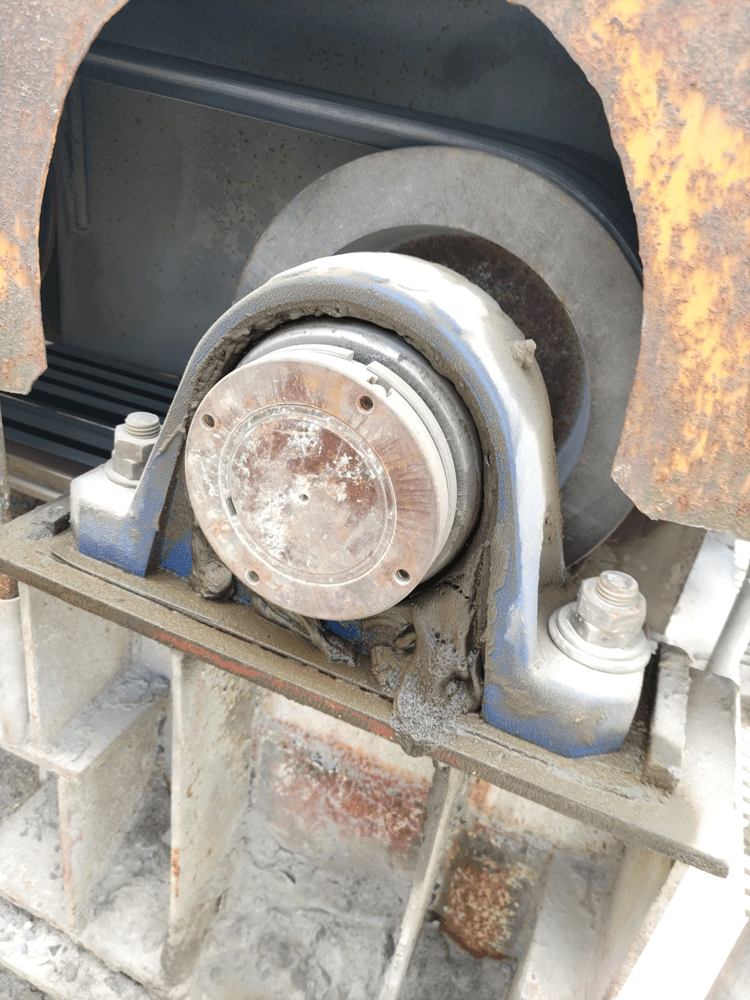

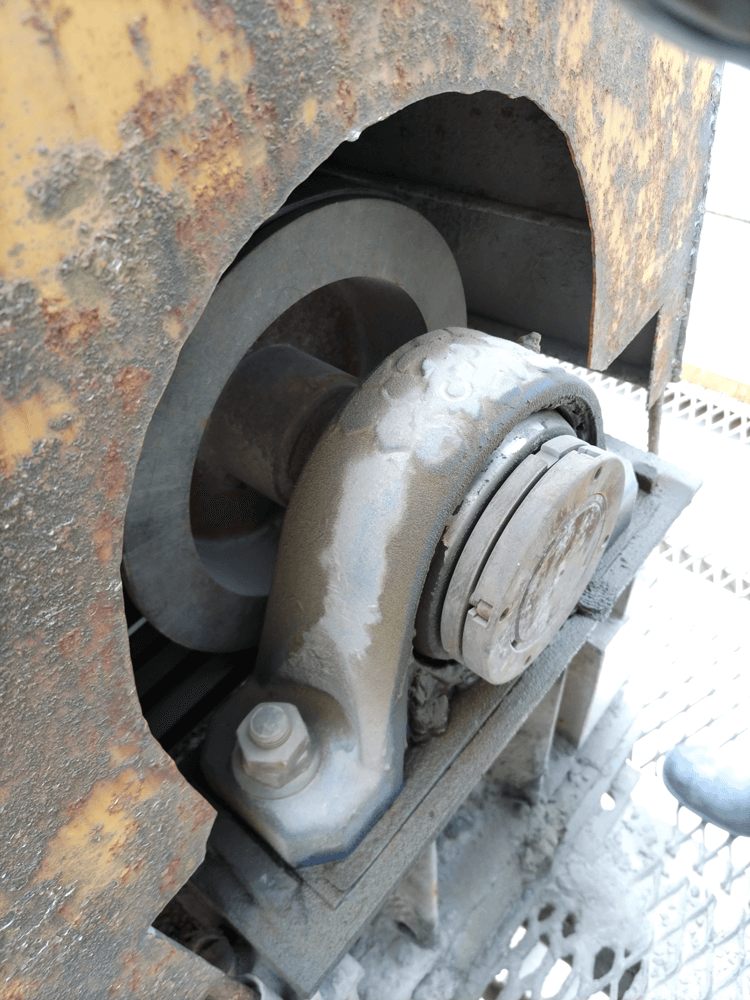

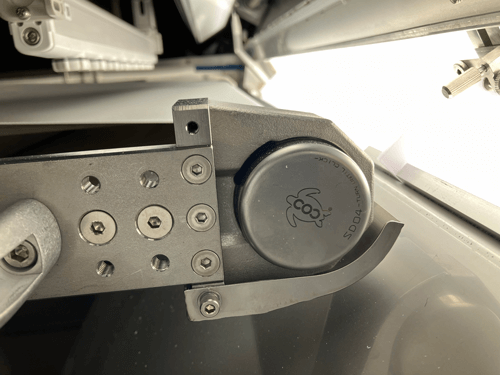

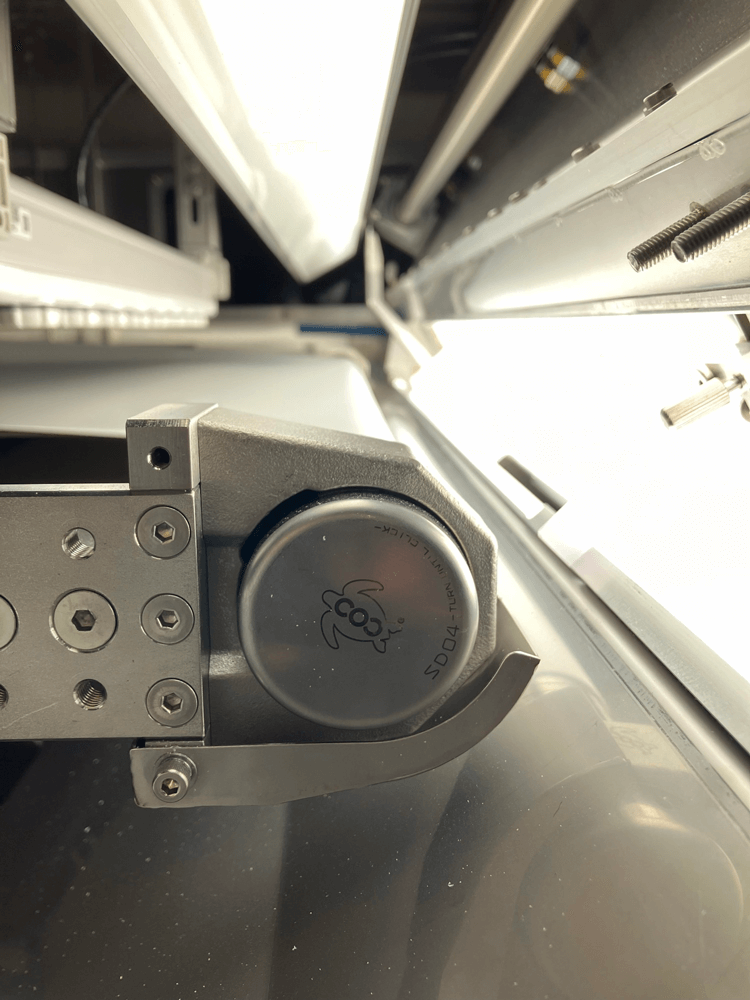

Sono passati cinque anni da quando hanno sostituito i cuscinetti a ralle convenzionali, che cambiavano ogni tre mesi, con i cuscinetti COC. Anche dopo cinque anni, i nostri cuscinetti funzionano ancora perfettamente e vogliono continuare a utilizzarli. La loro manutenzione consiste solo in una lubrificazione mensile.

Il risparmio sui costi è stato notevole—coprendo cinque anni di sostituzioni (quattro volte l’anno), manodopera per montaggio e smontaggio, e tempi di fermo macchina.

E questi risparmi sui costi dovrebbero continuare anche in futuro.