CXC4P20-400 (E)

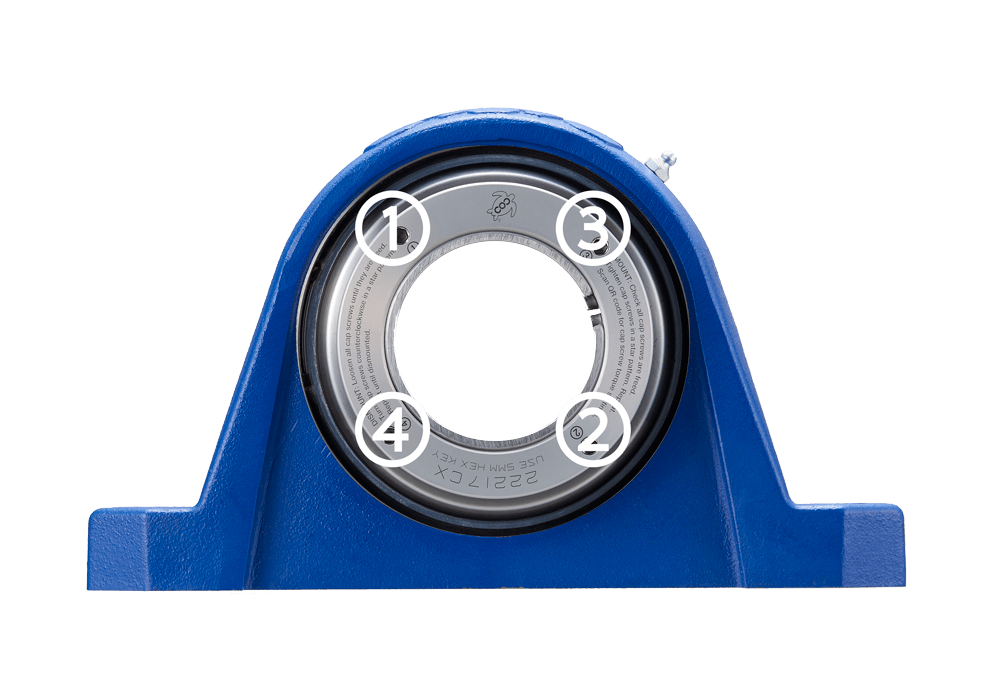

MOUNT:

1. Check all cap screws are freed.

2. Tighten cap screws in a star pattern. Repeat.

3. When using a torque wrench, first tighten each cap screw to 50 percent of the specified torque value, and then tighten them again to the full 100 percent torque value. Make sure to use a star pattern both times.

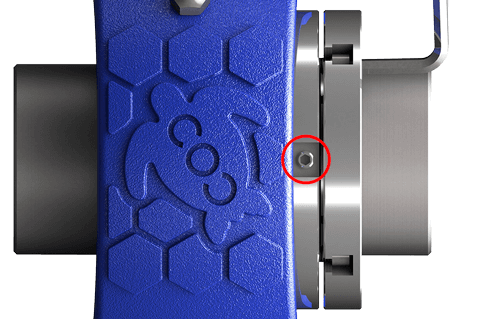

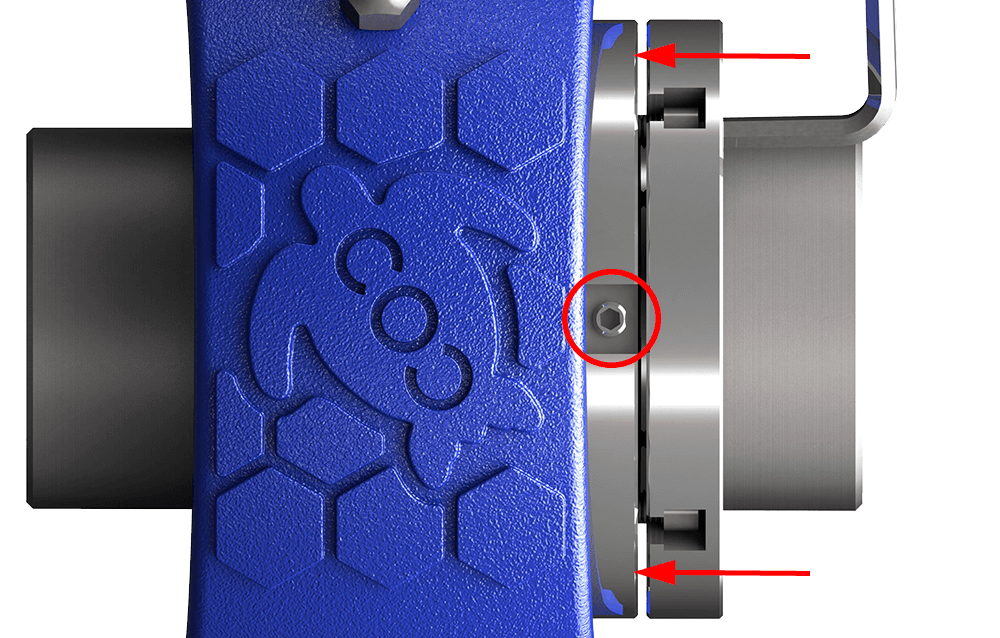

4. Tighten the setscrew circled in red in the picture below.

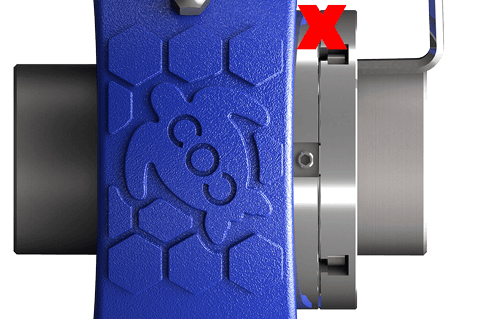

5. All the cap screws should be fully tightened to the recommended torque, and there should be a gap between the two nuts.

If the outer nut contacts the inner nut during tightening and there’s no gap between them, it means the shaft is too small. In that case, loosen the cap screws to return the nut to its original position, then slightly move the sleeve further inward by loosening it. This allows the sleeve to travel further in and fit the smaller shaft.

Please refer to the ‘Recommended Shaft Tolerance’ section below.

Note: The outside nut should move parallel to the inside nut to avoid the cap screws twisting and getting damaged. This is why the cap screws are tightened in a star pattern and repeated. You may need to repeat this several times to tighten all the cap screws perfectly, this is a very standard way as seen with automobile wheels.

DISMOUNT:

1. Loosen the setscrew(s) on the inner nut.

2. Loosen all cap screws unitl they are freed.

3. Turn cap screws counterclockwise in a star pattern and repeat until dismounted.

Recommended Shaft Tolerance : -0.004 in. / -0.102 mm

When the shaft is smaller than above, you can try below.

FIX TO EXPANSION

When your application needs to be able to accommodate thermal expansion of the shafting, use only one fixed bearing on each shaft.

By simply moving a snap ring on the back of the unit the bearing can easily be converted from non-expansion to expansion or vice versa.