CXC4P22-110 (E)

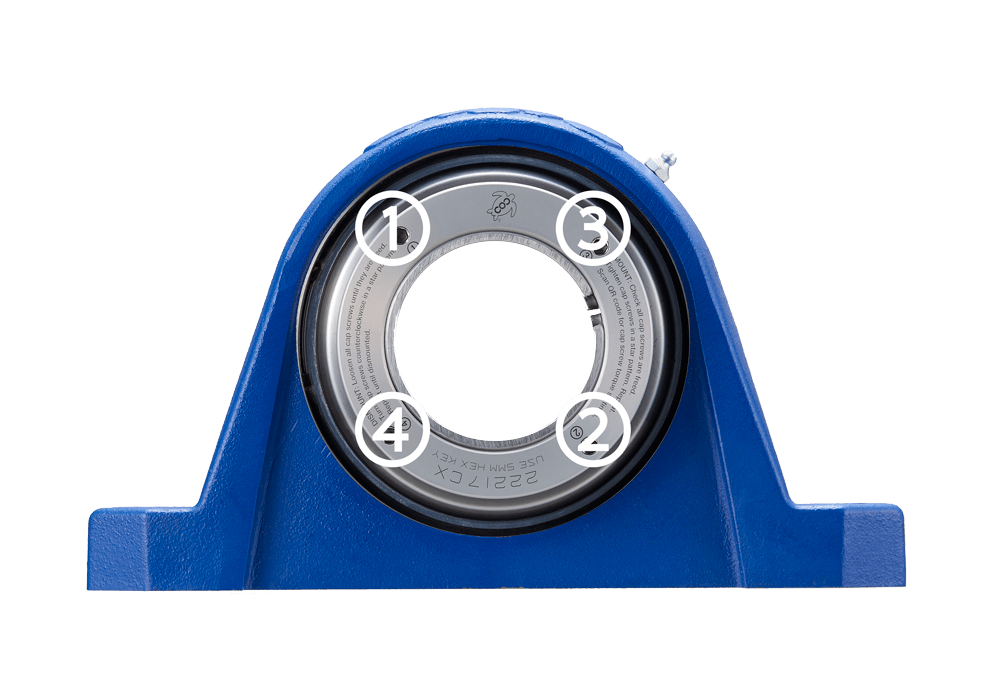

MOUNT:

- Check all cap screws are freed.

- Tighten cap screws in a star pattern. Repeat.

- When using a torque wrench, tighten each cap screw to the appropriate torque value above.

Note: The adapter sleeve needs to be pulled to lock and we use the left-hand cap screws to turn clockwise to pull. When you tighten the cap screws, the gap between two nuts gets bigger and the adapter sleeve is moving towards the outside. The outside nut should move parallel to the inside nut to avoid the cap screws twisting and getting damaged. This is why the cap screws are tightened in a star pattern and repeated. You may need to repeat this several times to tighten all the cap screws perfectly, this is a very standard way as seen with automobile wheels.

DISMOUNT:

- Loosen all cap screws unitl they are freed.

- Turn cap screws counterclockwise in a star pattern and repeat until dismounted.

Note: When you want to unlock CROSSLOC™, loosening and turning counterclockwise is needed. They are the same left rotation but turning counterclockwise does not loosen. Loosen all cap screws to be freed first. Then you need to push the outside nut to release the adapter sleeve from the inner ring. Turn the cap screws counterclockwise in a star pattern and repeat until dismounted. It’s same as locking and the outside nut should move parallelly.